The range of applications for linear drives in the medical and pharmaceutical sector is very broad.

For handling blood samples, counting and filling pills, or packing challenging medications, LinMot drive components provide a high level of dynamics and precision for implementing these tasks.

The hygienic design of the linear motors makes it possible to cleanly process these highly sensitive products in accordance with clean room regulations.

Customers benefit from experience with drive solutions that have already been implemented in the areas of:

LinMot has developed special stainless steel modules for applications in the medical & pharmaceutical industry. Designed for a demanding environment, the compact LinMot SSC linear motors are made of stainless steel EN 1.4404/AISI 316. To prevent the build-up of dirt, the motors are designed without unnecessary edges, corners as well as holes and screw connections. They can be used in machines and systems for processing food or in the pharmaceutical industry. There, they can easily cope with extremely rough or corrosive environments and can be cleaned without hesitation using all standard industry cleaning agents.

An overview of all LinMot products is available on this page:

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

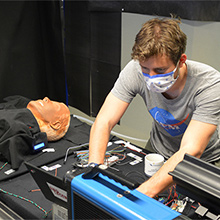

Medical nose-and-mouth masks can help to reduce the spread of the COVID-19 virus. Additional simple measures significantly increase their protective efficacy. This has been confirmed in systematic, reproducible investigations by the OTH Regensburg with a lung simulator that uses linear motors from LinMot.

With over 6 billion products processed every year, and the cutting-edge linear drive technology from LinMot, the unique coding machines from Hicof are the tip of the spear in the fight against counterfeiting.

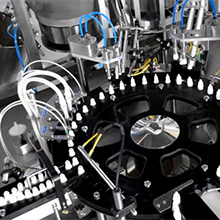

Multiformat filling and sealing system at Zellwag Pharmtech AG with precision linear rotary motors from LinMot.

As a leader in the MENA area for pharmaceutical machines and production lines, AFAQ puts a lot of effort in comparing and selecting state-of-art systems to be used in its Ophthalmic Drop Filling and Closing Machine (DropFill-SC) series.

Dynamics in the filling and sealing machine industry. Since 2002 Zellwag AG has put their trust in linear motors when building their fully automated filling and sealing machines for pharmaceutical and cosmetic products.

Linear motors are a particularly good solution for pharmaceutical cleanroom applications. They experience very little abrasive wear, require little lubrication at widely spaced intervals, and are easy to clean. For these and other reasons, they are now the state of the art for the noted Swiss primary packaging producer Hoffmann Neopac AG and an indispensable part of modern pharmaceutical production systems.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information