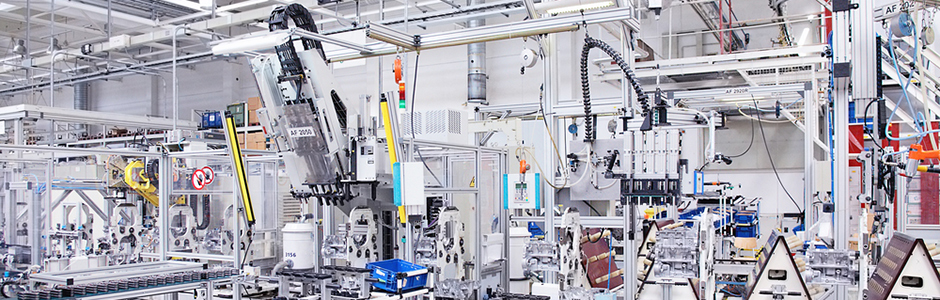

With freely programmable and highly dynamic linear motors, the plant engineer finds the optimum components for a modern production machine that can easily withstand the applicable requirements.

In the global competition the “time-to-market” period has become an increasingly promising factor. Shorter innovation cycles and large model variety are the greatest challenges. To meet these requirements, it is necessary to have a flexible production with intelligent automation solutions.

Main approach for more efficient production systems are modular systems in which elements can be reconfigured easily. The integration of additional modules with new functionalities into existing lines should be easily implemented with the aim to increase the reusability of the production plant. In addition to an increased flexibility, a modern facility requires a maximum production speed and a secure traceability in the form of a complete electronic process documentation.

With freely programmable and highly dynamic linear motors, the plant engineer finds the optimal components for a modern production machine.

Numerous applications that have already been implemented show that LinMot drive technology can significantly increase the productivity and flexibility of assembly and handling systems, and plug&play technology significantly shortens commissioning times. The range of applications includes all conceivable drive tasks.

The range of applications covers all possible drive tasks:

Flexible and fast as lightning: Direct electrical drives can be used to build pick&place modules that are highly efficient, precise, and dynamic. They are also more flexible, more compact, and require less effort to install and maintain than their pneumatic or cam-driven counterparts.

Just think of the battery-powered lawn edger back in 1973 or the watering computer from the 1980s, GARDENA has always proven to be a particularly sustainable innovator. With state-of-the-art linear rotary and linear technology from drive specialist LinMot, GARDENA has succeeded in redefining the precision, speed and sustainability of its production facilities.

By switching from pneumatic cylinders to linear motors, the machine and plant manufacturer Keller HCW has succeeded in developing an innovation in universally applicable robot grippers with high payloads that can even grip, separate and move sensitive products safely and gently.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information