Most food products that we use no longer come directly from the producer. Rather, they pass through a number of industrial processing and packaging steps before they show up on the supermarket shelf or land in our grocery carts. Automation technology is a fundamental building block for all food product and packaging machines. Frequently changing packages in smaller and smaller batches, or larger production quantities , are some of the common challenges for machine builders. An additional requirement is the complete monitoring and record-keeping of all processes. Every manufacturer and process of food products wants to have safe, monitored production of their goods. Consumer protection must be strictly adhered to for all products, in terms of current hygiene regulations.

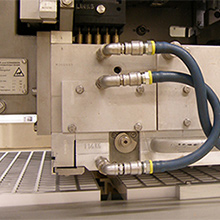

LinMot drives provide machine builders with optimal components for putting the manufacturing and packaging processes in motion in the food products industry.

Various models of linear motors with highly hygienic stainless steel designs have been developed especially for this purpose.

They can perform standardized, highly dynamic, linear or linear-rotary motions in the housing of a single motor type.

In combination with freely programmable motion parameters via the drive, the motors provide a high level of flexibility for applications such as:

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Skala Maskon has developed the VX-8 machine, which can automatically vaccinate up to 20,000 fish per hour. This revolution in fish farming is made possible by the use of a high-performance image processing system in conjunction with dynamic, compact stainless steel linear motors rated at IP69K from LinMot.

Ever since Chocolat Frey AG recently expanded their production of the highly popular Napolitains, this large Swiss chocolate maker has benefited from the advantages of advanced technology, producing a wide assortment of very small chocolate wafers with even greater quality, process reliability, and productivity.

Valka, an Icelandic hightech company that designs and builds progressive systems for fish processors, is equipping its grading and sorting machinery with LinMot stainless steel motors for the speed and accuracy demanded in a difficult washdown environment.

Food Technology Thielemann, which specializes in poultry slicers, has introduced the world’s first solution for this task. Using lean, hygienic linear motors made of stainless steel from LinMot, the high-output vertical slicer has been kept simple in design for high energy efficiency and performance.

Bulky construction, bottles falling over and low line performance – all that is a thing of the past. The state-subsidised developments of Syscona Kontrollsysteme GmbH, paired with linear motors from LinMot, together pave the way for a demand-oriented and digital structural change of production and control processes in the beverage industry.

200 million litres of milk and 60 million litres of cream. These impressive quantities of liquids are processed annually at Emmi’s Mittelland Molkerei AG in Suhr. Right in the center of it all: LinMot’s lifting rotary motors and Wing-Cap closures.

Many users wish they could combine the advantages of flow-rate metering and piston metering in one rotary filling machine. Tölke, a specialist in packaging machinery, has pulled off this feat by using LinMot linear motors.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information