Biofluid researchers test protective efficacy of masks: Medical nose-and-mouth masks can help to reduce the spread of the COVID-19 virus. Additional simple measures significantly increase their protective efficacy. This has been confirmed in systematic, reproducible investigations by the OTH Regensburg with a lung simulator that uses linear motors from LinMot. The motors helped researchers to set up and starting running the tests in just a few days.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Video of a breath. First without mask, then with mask (Video: OTH Regensburg)

Revealed in the light: In Prof. Dr.-Ing. Lars Krenkel›s laboratory, the fan-like laser makes the smoke that escapes under the edges of a medical nose-and-mouth mask clearly visible. It consists of particles ranging from 200 nm to 2 μm and is thus suitable for modelling the aerosols exhaled by people. The dummy shows the most smoke escaping from the areas abovethe cheeks and adjacent to the nasolabial folds. This makes it clear that medical personnel such as paramedics or anesthetists, who spend a lot of time above or in close proximity to a sick patient’s head, are exposed to a risk of infection even if the patient is wearing this kind of mask. “Mask are fundamentally unable to provide 100% protection, if only because of the potential to use them incorrectly. Nevertheless, it would be wrong to say they offer no protection whatsoever,” says Prof. Krekel, head of teaching and research for the field of Biofluid Mechanics in the Mechanical Engineering department at the OTH Regensburg. “Simple optimization measures for medical nose-and-mouth masks can provide up to 85% retention with respect to aerosols and around 95% for droplets, substantially increasing their protective efficacy.”

Contaminated aerosols potentially more dangerous

When investigating the path of infection, epidemiologists closely observe aerosols, which are respirable and can remain in the air for a long time due to convection. Aerosols include particles on the scale of about 100 nm to 5 μm. They penetrate to the bronchi and, if they carry a virus, can cause lung infections there. Particles in the range of 5 to 10 μm, in contrast, do not penetrate any further than the glottis. Larger droplets, up to about 100 μm, are captured in the nose or throat, so they typically cause only mild illness. They are subject to the laws of ballistics and cannot remain in the air over long distances (only about 1.5 m). The risk posed by contaminated droplets is therefore estimated to be low overall and easier to manage. Particles above 100 μm in size cannot be inhaled at all under normal circumstances. In order to cover all of the relevant transmission paths for particles, Prof. Krenkel’s team is investigating propagation mechanisms of both aerosols and droplets under the most realistic possible conditions. “Our research, in cooperation with the university clinics in Hamburg Eppendorf and Regensburg, is focused on investigating the protective function of masks under various boundary conditions and on identifying and quantifying optimization measures.”

Linear motors help researchers

Since the lab for biomedical and biological flow testing opened in 2014, Prof. Krekel’s team has gained extensive experience in setting up test arrangements for experimental and numerical flow testing in biological, medical, and technical systems. The researchers have emulated and analyzed processes in the human bloodstream and airways. To investigate airway processes, the researchers needed a “passive lung” that could simulate the pressure and volume behavior of the human respiratory organ. Due to the compliance of the lung tissue, the pressure-volume curve is not linear, but rather S-shape (sigmoidal), and is different for inhalation and exhalation. This meant that an air vessel or similar apparatus would not work. The same situation applies to simulation of the heart. Here as well, simple systems soon meet their limitations. Eccentric pumps driven by stepper motors, for example, can only simulate linear dependencies and give researchers little flexibility. “We needed something that can be controlled quickly but precisely,” says Prof. Krekel, summarizing the requirements for the desired solution.

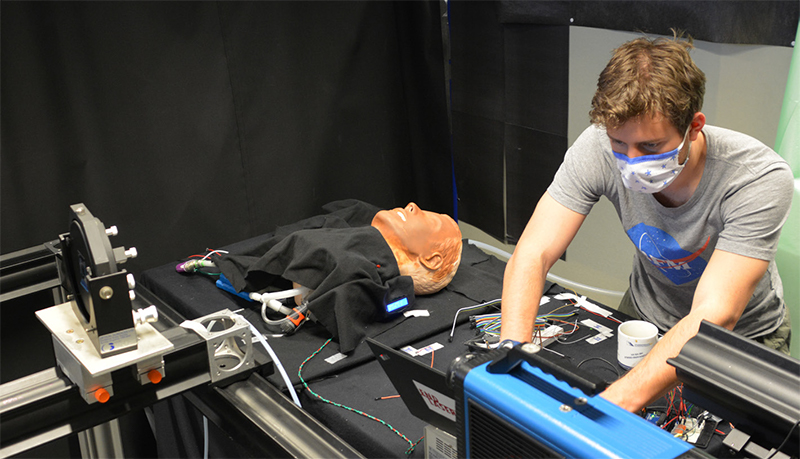

Researchers at the OTH Regensburg use a resuscitation trainer to investigate the protective efficacy of nose-and-mouth masks in the fight against the spread of the COVID-19 virus. (Photo: Rossmann)

Universal motor-pump system

The researchers ultimately decided on two LinMot linear motors, model PS01-48x240F-C, with IP67 protection class, for moving the pistons of a cylindrical linear pump system. A valve system provides pressure regulation and the introduction of media (air, blood substitute) into each cylinder. The linear motors are supplied by LinMot Servo Drives and monitored and coordinated by an industrial control unit that is often used in machinery. The researchers benefit from the flexibility that linear motors provide. The test system can realistically and reproducibly simulate the continuously pulsating pressure-volume behavior of a healthy heart, or a sick one as well. The researchers used the same system to simulate a passive lung that is able to reproduce the consequences of changes due to illness. This includes the distribution of air between lobes of the lungs.

Faster initial test results

The flexibility of the system recently helped the researchers when the acute COVID-19 pandemic drove the search for fast answers to the urgent question of how well medical nose-and-mouth masks can protect medical personnel. At the beginning of March, 2020, hospitals brought this question to Prof. Krenkel’s research team, who developed an appropriate test setup within a few days. Linear motors again played an important role. They are the core of an artificial respiratory system and produce a variable airflow. With programmable parameters for “acceleration,” “travel speed,” and “stroke,” the researchers were easily able to implement various breathing scenarios, such as normal breathing, coughing, and hypoxia. They used the LinMot Talk engineering and configuration tool to create various motion profiles. From the user interface for the industrial controller, the researchers can save these profiles and call them up directly from the control program, in any order, and if necessary even while the program is running. When creating the profiles, the researchers were helped by the fact that the stroke-to-volume relationship is proportional for the combination of a linear motor and a linear pump, so that the curves found frequently in literature that show volume over time were easy to implement.

Test automation using industrial components

“We also found it to be beneficial that we could combine the LinMot motors with very universal and highly advanced systems, such as Beckhoff or B&R controllers. These companies also offer a wide range of different I/O and interface modules,” explains Prof. Krenkel. “We can completely automate the entire test run, synchronize the systems, and thus ensure high reproducibility.” For example, the aerosol generator and the valve that controls the infeed to the linear pump are connected to a 24V output terminal, so that the particles can be drawn in by the pump piston at precisely the right time.

Summary

“As of mid-May, 2020, the data shows that medical masks can retain 65% to 75% of aerosols at the primary level, depending on their design. At the ancillary level, filter efficacy depends greatly on how well the mask is fitted and the physical constitution of the wearer,” says Prof. Krenkel, summarizing the results of a series of tests performed over six weeks. “Using simple measures, such as attaching the mask by taping the sides, 85% of aerosols can be retained and the escape of unfiltered air at the sides can be completely prevented.” The fact that initial, reproducible test results were available to researchers within just a few days was due in part to the use of the highly flexible linear motor system from LinMot. It can be used in many areas of biofluid mechanics, reducing the time and effort needed to set up complex test scenarios. Prof. Krenkel therefore intends to use the linear motor system increasingly in further research projects.

Read more about the linear motors from LinMot

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information