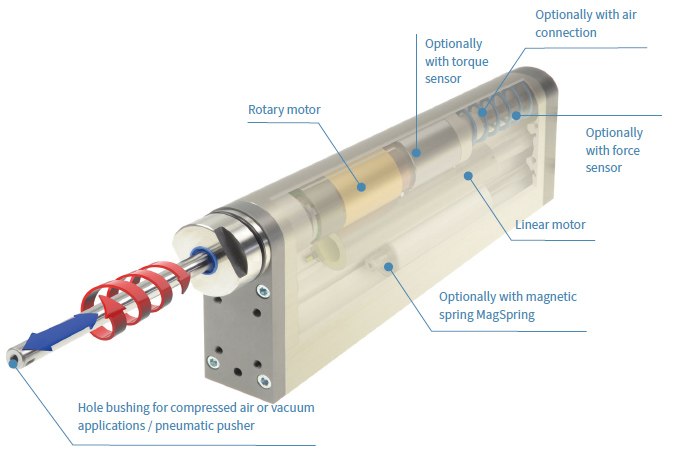

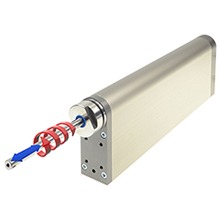

The PR02 motor series is characterized by a design wherein the motors and additional components are integrated in a slim easy to clean housing. Options can be installed such as a hollow shaft, pneumatic pusher, a magnetic spring “MagSpring”, a torque sensor, and a force sensor.

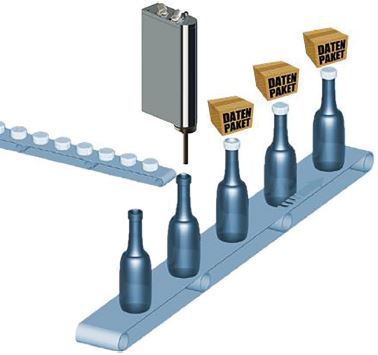

The innovative PR02 delivers all necessary data packages for networked production in the sense of “Industry 4.0”. With the help of real time motor information and optional additional sensors, detailed information, such as the vertical position, press force or impact force, closing angle and torque are available.

To the details in the e-catalogue

Option hollow shaft offers a feed through air possibility through the entire module for operating pneumatic grippers or for suck elements via vacuum. There is no need for a pneumatic hose around the module shaft and endless rotation is possible.

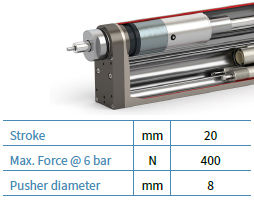

Option pusher allows users to have a second axial, telescopic movement. Gripping elements may be emitted or mechanical grippers are operated using this option. Integrated pneumatic cylinder is double-acting.

A properly sized MagSpring ensures that the tooling and motors moving mass are passively compensated for, preventing the axis from falling in event of a power loss. MagSpring force is available in different sizes and its working direction may be pulling or pushing.

Torque and force sensors enable precise, reproducible, and recordable capping and assembling processes often required in pharmaceutical or medical industries.

Due to continuous real time process monitoring every assembled unit can be traced.

The PR04-52 is a special version of the PR02-52 and has been optimised for applications that do not require additional integrated options. Instead, the new PR04 linear rotary motors offer a large stroke range of up to 200 mm. Its low weight makes it ideal for use as a vertical moving axis.

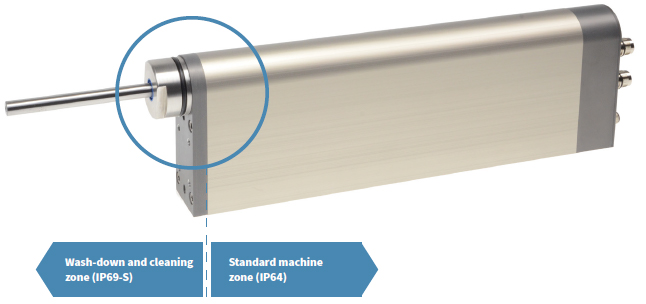

We now offer our proven PR02 linear motor in a hygienic stainless steel version for use in the chemical, pharmaceutical and food industries. This makes the PR02 even more versatile and resistant to cleaning agents, with minimal maintenance requirements.

To the details in the e-catalogue

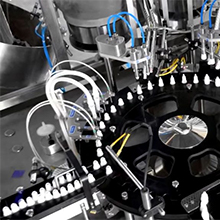

Here you can see the Tölke closing machine in operation. The entire process is carried out by a PR02 series linear rotary motors.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

With LinMot®, slim design and full functionality are no longer contradictions. The latest example of this is the PR02-40 stroke rotary motor. With an overall width of just 40 mm, it is the most compact drive in the PR02 series, yet offers all the optional features of its larger counterparts.

For filling and packaging applications, where great precision and process reliability are needed, LinMot has now brought to market linear rotary motors with integrated sensors. They are not only extremely reliable and precise, but also collect process data for every closure operation.

The Pharmaceutical sector is considered as one of the most demanding sectors in the industrial field. Machine designers and builders must consider and respect many rules and standards and should mandatorily apply the cGMP (current Good Manufacturing Practices). These rules and guidelines become more restricted when the machine is handling aseptic medicine, such as Ophthalmic Drops.

For applications in filling and packaging technology where maximum precision and process reliability are required, LinMot has now launched rotary lifting motors with integrated sensor technology. Not only do they work particularly reliably and accurately, but they also provide the collected process data for each capping process.

Just think of the battery-powered lawn edger back in 1973 or the watering computer from the 1980s, GARDENA has always proven to be a particularly sustainable innovator. With state-of-the-art linear rotary and linear technology from drive specialist LinMot, GARDENA has succeeded in redefining the precision, speed and sustainability of its production facilities.

We will be happy to answer any questions you may have about the linear rotary motors.

Please contact us using the following form or call us at

Tel: 262-743-2555

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information