With the new application “Process Monitoring” LinMot takes the next step towards Industry 4.0.

In order to increase quality, to make rapid process adjustments due to external influences or to ensure the traceability of each individual product, it is necessary to have the best possible knowledge of the actual process. LinMot drives are characterised by their very fast cycle time and can therefore record individual measuring points with the highest possible sampling rate. This gives the user a detailed process picture and, based on this data, he can decide whether the process is successful or not.

“The control system is not only able to assess the process after it has been completed, but also to adjust it “on the fly” and react directly to process influences.”

By means of process monitoring, the user can monitor his process in a simple way. The decisive measured variables for the process can be recorded and evaluated. In addition to the actual process monitoring, this can also ensure consistent quality, process the data for the purpose of analysis functions or even implement predictive maintenance. This means that nothing stands in the way of data analysis in accordance with Industry 4.0, which is increasingly required in mechanical engineering in particular.

“Continuous process monitoring in real time means that every assembled unit can be traced back”

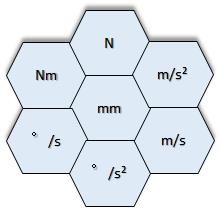

Monitoring of any variables possible (above figure not exhaustive).

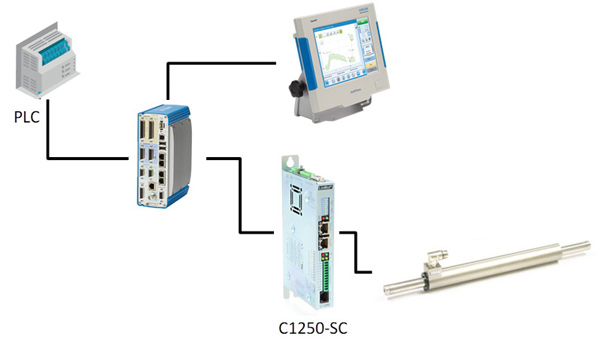

Flexible process monitoring: LinMot products are compatible with third-party process monitoring systems. This enables evaluation of highly dynamic processes at the highest level.

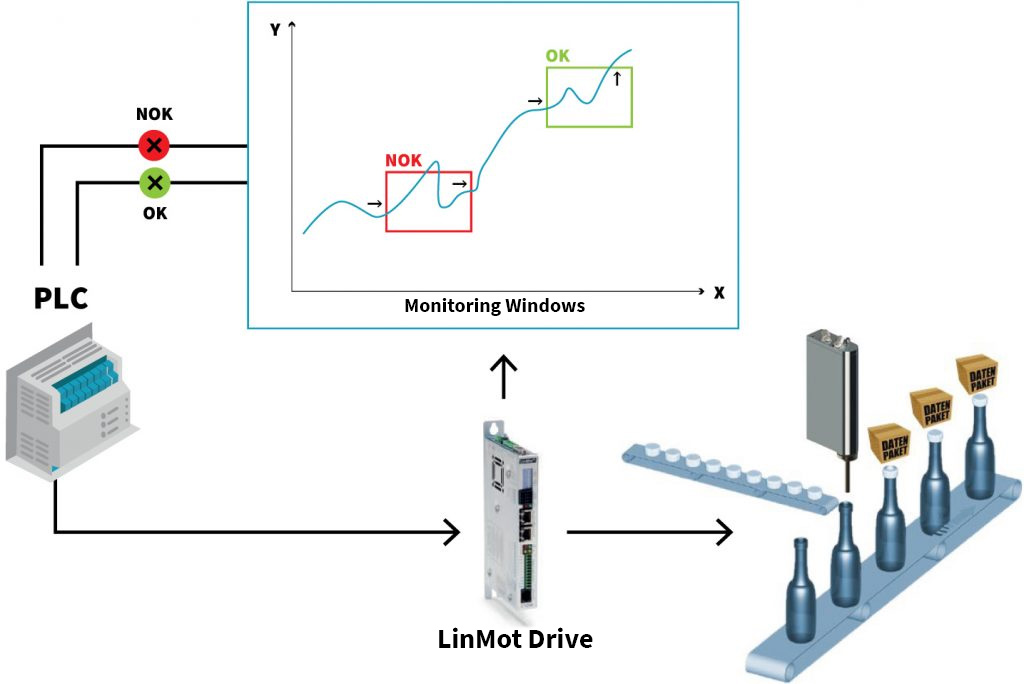

Process monitoring systems can monitor and evaluate the quality of a product or manufacturing step based on an XY curve. With the help of evaluation elements, the user adapts the curve evaluation to the individual monitoring task. According to this specification, the system decides on good or bad for each individual workpiece.

Highly dynamic applications such as insertion, testing, inspection or assembly, e.g. also via pick’n’place setup, can be easily controlled, monitored, evaluated and documented in conjunction with LinMot linear motors and the associated servodrives of the C1250-SC series. Based on the shape of the recorded XY measurement curves, the quality of each individual production step, an assembly or the entire product can be monitored and controlled in real time.

Bulky construction, bottles falling over and low line performance – all that is a thing of the past. The state-subsidised developments of Syscona Kontrollsysteme GmbH, paired with linear motors from LinMot, together pave the way for a demand-oriented and digital structural change of production and control processes in the beverage industry.

We will be happy to answer any questions you may have.

Please contact us using the following form or call us at

Tel: 262-743-2555

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information