Gripping, positioning, stacking, aligning or centring: The new LinMot GM01 series gripper module is designed for precise gripping and moving of products in the most demanding environments.

With the high flexibility of the new gripper module’s adjustment options, LinMot is once again one step ahead of the competition. How so? The special arrangement of the gripper’s two durable tubular linear motors allows each jaw to be controlled independently. This means that the GM01 can not only gently grip and transport dry, moist, hard or soft products without leaving visible marks, but can also move them axially to the left and right of the gripper. This makes it possible to use special gripping tactics (e.g. the shovel-broom principle) that cannot be achieved with a conventional gripper. In addition, the LinMot GM01 is easy to clean and its hygienic design and high IP69 protection rating make it ideal for use in the food industry. Thanks to the position detection of the gripper and the control of the clamping force, even products with a non-uniform shape can be gripped safely. One of the key benefits of the GM01 series of intelligent grippers is the wide range of monitoring options that are essential for applications with a high degree of automation. This means that faulty gripping or even faulty parts can be detected and sorted out “on the fly”.

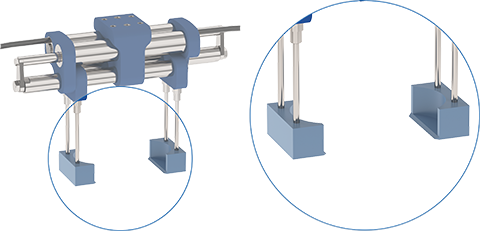

The dynamic and flexible characteristics of the LinMot linear motors integrated in the gripper make it possible to grip countless product shapes. To meet even more individual process requirements, the gripper jaws can also be customised by the customer and adapted exactly to the characteristics and shape of the product. Thanks to the flexibility of the LinMot GM01, each gripper unit can be adjusted and moved as required, both in terms of force and position, despite the customised design of the gripper jaws. Whether it is round products with a delicate surface, the collation of several products according to the “shovel-broom principle” or large and flat products with a sticky surface, the LinMot gripper modules offer a flexible, adaptable solution that is optimally matched to the product characteristics.

The gripper closes until the product is gripped or lightly touched. Regardless of the size, it is possible to check that a product has been gripped correctly. To prevent slipping, the contact pressure can be increased (depending on the transport dynamics). The product can be set down by opening one or both gripper jaws slowly or quickly. With the measurement, control and storage of information such as position, force and even temperature, process steps are 100% verifiable and traceable.

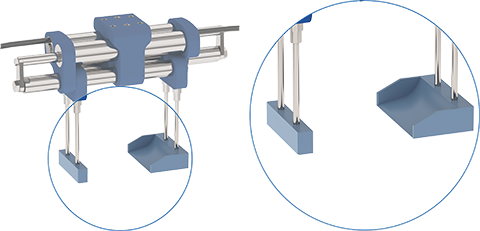

The gripper (left) pushes the product onto the shovel (right). The shovel is placed in front of the product and then the broom gently pushes the product into the shovel. This also allows multiple items to be loaded. By applying slight pressure during transport, the broom can prevent the product from falling out. Unloading is done with a quick jerk to remove the products from the shovel and place them in a defined location.

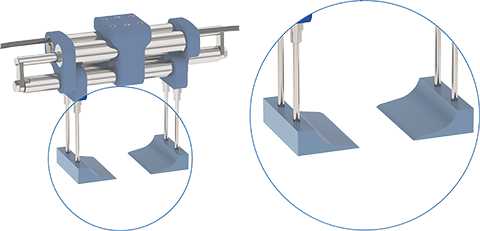

To gently lift sticky and adhesive products, such as a chicken breast, from the surface, the gripper jaws are gently moved under the object to be gripped. Just before the product is placed, the gripper is opened halfway. This allows the product to adhere to the substrate before the gripper jaws are fully separated for precise and gentle placement.

The GM01 gripper module adds a further element to the LinMot stainless steel line by means of simple coupling and material standardisation. Together with the SM01 guide, a complete pick-and-place application in stainless steel EN 1.4404 can be constructed: the two linear modules SM01 realise movements in X and Z direction, while the GM01 can additionally move the gripped product in Y direction. A complete LinMot solution, characterised by very high resistance to chemical influences and an enormous service life, even under difficult conditions.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information