MagSpring products are best described by the term “magnetic spring”. The term “spring”, however must be understood in the sense that MagSpring components exert a constant force over their entire working range, whereas a typical characteristic curve for a mechanical spring has the force increasing as a function of displacement. Generating a force that is independent of displacement makes MagSprings an excellent choice for compensating for weight forces in vertical drive arrangements.

The product consists of two main components. The stator surrounds the centrally located slider. Depending on the force rating of the MagSpring, permanent magnets are located either in the stator, in the slider, or in both components. The slider is supported by an integrated sliding bearing, so that MagSprings can be used similarly to gas pressure springs.

Constant force over the entire stroke

Its functionality is based on the attractive force of permanent magnets. This means that no power supply is needed (electrical power, compressed air, etc.), making even safety-related applications possible. Due to the special design of the flux guiding components and the magnets, the severely non-linear relationship between force and displacement in arrangements of magnets and iron is transformed into a constant force curve.

Fail safe functionality and weight compensation

The constant force over the entire range of the stroke makes it an excellent fail safe and weight compensation when installed vertically. Thanks to the MagSpring providing weight compensation, the linear motor is used only for positioning and for applying dynamic forces, so it can be sized correspondingly smaller.

To the details in the e-catalogue

Thanks to the constant force to displacement curve, many other applications are possible in addition to weight compensation for a vertical installation. For example, generating a constant press force regardless of location, applying a constant supporting force over a wide stroke range, or applying a force on only one side for complex drive tasks.

The stators can be mounted using either the fine thread or a clamp. A suitable mounting flange is available for each of the two sizes. When attaching the slider to the load mass, take care to compensate for parallel alignment errors with a flexible mounting method.

If the electrical power supply is interrupted, the MagSpring also prevents vertical axes from dropping down to their bottom stop position. If the force of the MagSpring is greater than the force of gravity, then the axis is drawn up to the top end position.

Because MagSprings are purely passive elements, a defined function or location of a device can be ensured if the power is cut off. For example, lifting a gripper or a press head in a vertical arrangement, or retracting or extending a pusher with a constant force.

For a vertical installation, linear motors and other direct drives must continuously apply a constant force in order to act against the force of gravity. With a MagSpring installed in parallel with the linear motor, the weight can be passively compensated. The linear motor is used only for the actual positioning or for applying the dynamic forces, and can be sized correspondingly smaller.

Thanks to the constant force to displacement curve, many other applications are possible, such as applying a constant press force regardless of position, applying a constant retaining force over a large stroke range, or one-sided force support in drive tasks. The effective force is in the range of +/-10% of the nominal force.

In case of a power off situation the MagSpring will retract the shaft of the linear-rotary motor into a safe position.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

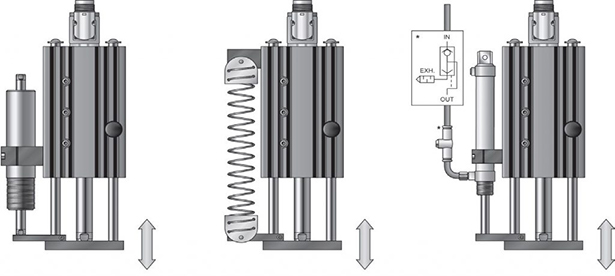

In order to get fast cycle times when direct drives are mounted vertically, or to prevent an axis from crashing down when the power is shut off, the intrinsic weight must be compensated for. Mechanical springs and pneumatic systems have been primarily been used up to now, but they have their disadvantages. In many cases a “magnetic spring” from MagSpring is a better solution.

We will be happy to answer any questions you may have.

Please contact us using the following form or call us at

Tel: 262-743-2555

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information