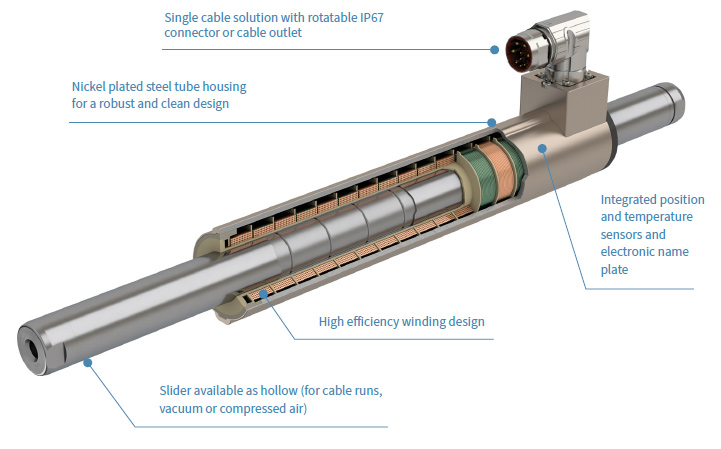

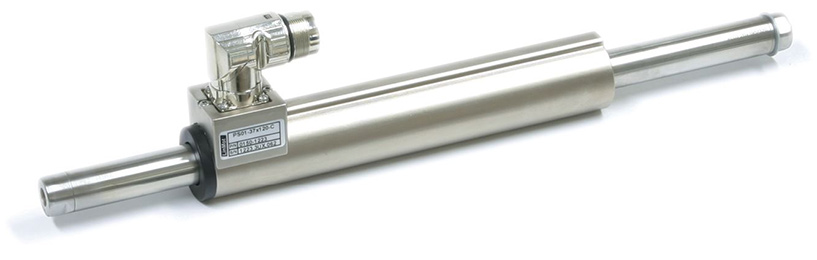

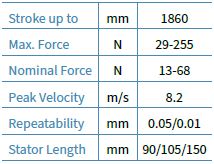

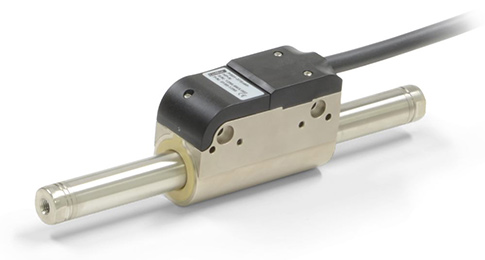

LinMot P01 linear motors are permanently actuated ironless synchronous servo motors with integrated position measurement and over-load protection. Powerful rare-earth magnets in the slider and windings in the stator are used to directly generate the linear motion.

Universal

Compact

In this video you can see twelve LinMot linear motors in use.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Ever since Chocolat Frey AG recently expanded their production of the highly popular Napolitains, this large Swiss chocolate maker has benefited from the advantages of advanced technology, producing a wide assortment of very small chocolate wafers with even greater quality, process reliability, and productivity.

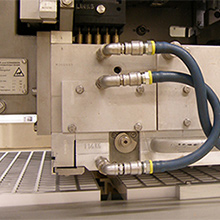

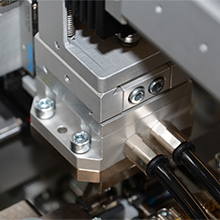

Flexible and fast as lightning: Direct electrical drives can be used to build pick&place modules that are highly efficient, precise, and dynamic. They are also more flexible, more compact, and require less effort to install and maintain than their pneumatic or cam-driven counterparts.

Dynamics in the filling and sealing machine industry. Since 2002 Zellwag AG has put their trust in linear motors when building their fully automated filling and sealing machines for pharmaceutical and cosmetic products.

Linear motors are a particularly good solution for pharmaceutical cleanroom applications. They experience very little abrasive wear, require little lubrication at widely spaced intervals, and are easy to clean. For these and other reasons, they are now the state of the art for the noted Swiss primary packaging producer Hoffmann Neopac AG and an indispensable part of modern pharmaceutical production systems.

Bulky construction, bottles falling over and low line performance – all that is a thing of the past. The state-subsidised developments of Syscona Kontrollsysteme GmbH, paired with linear motors from LinMot, together pave the way for a demand-oriented and digital structural change of production and control processes in the beverage industry.

75 billion US dollars per year. According to the World Health Organisation (WHO), this is the estimated market value of counterfeit medicines worldwide. An untenable pharmaceutical policy status quo. With over 6 billion products processed per year and with LinMot’s leading linear drive technology, Hicof’s unique coding machines spearhead the initiative in anti-counterfeiting.

By switching from pneumatic cylinders to linear motors, the machine and plant manufacturer Keller HCW has succeeded in developing an innovation in universally applicable robot grippers with high payloads that can even grip, separate and move sensitive products safely and gently.

Medical nose-and-mouth masks can help to reduce the spread of the COVID-19 virus. Additional simple measures significantly increase their protective efficacy. This has been confirmed in systematic, reproducible investigations by the OTH Regensburg with a lung simulator that uses linear motors from LinMot.

Guaranteeing optimal packaging results every time, even when product characteristics vary and product types change frequently, is one of the greatest challenges facing a machine builder. Alpenland Maschinenbau GmbH, or ALPMA for short, has taken on and successfully overcome this challenge.

We will be happy to answer any questions you may have about the linear motors.

Please contact us using the following form or call us at

Tel: 262-743-2555

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information