In today’s fast-paced industrial environment, speed and precision in closure and screwing processes are of crucial importance. Conventional methods are reaching their limits in meeting the increasing demands. Read our blog to find out how LinMot linear rotary motors are taking the efficiency, accuracy and reliability of closure and screwing processes in industrial applications to a new level.

There are a number of challenges that companies face in their closure and screwing processes. The need to increase productivity is certainly one of them, along with the need for greater flexibility – especially when producing small batches – and the need for process stability. These challenges, if not addressed, can lead to significant inefficiencies, variations in product quality and overall customer dissatisfaction.

The situation is further complicated by the shortage of engineers with specific skills, which requires solutions that are not only reliable, accurate and versatile, but also efficient in terms of time.

As a result, companies needed more effective solutions to overcome these challenges and improve the efficiency of their processes.

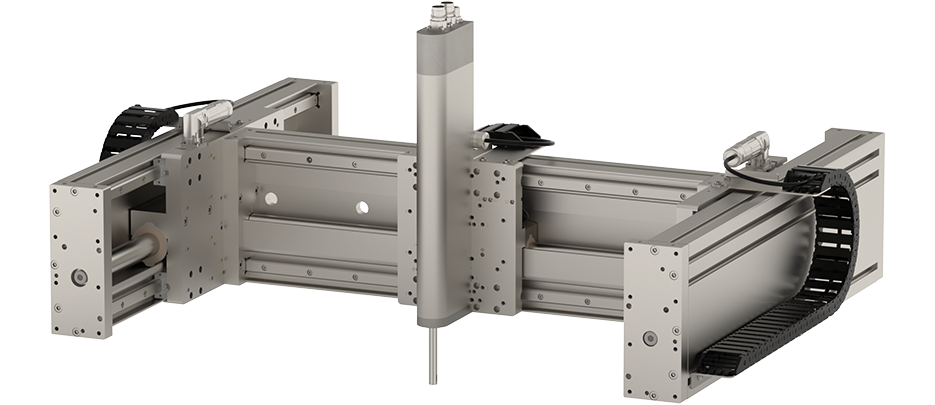

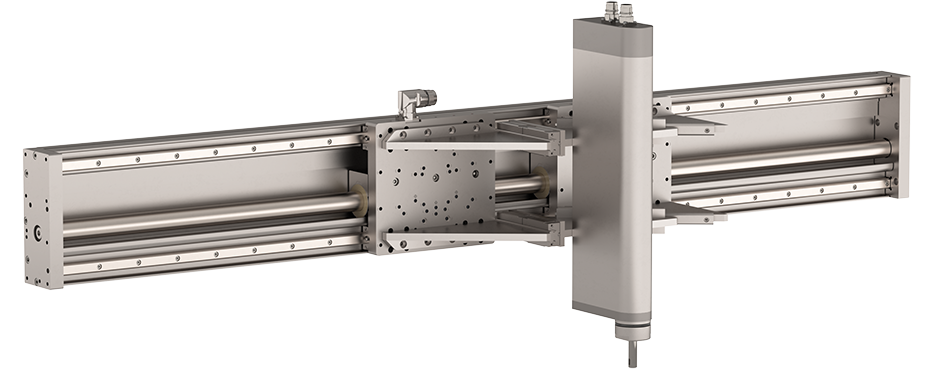

The use of our linear rotary motors has enabled companies to effectively overcome these challenges by introducing a single standard element with integrated technologies that is compact, easy to assemble and provides fast, precise and reliable linear and rotary motion in one module. Process stability is also guaranteed thanks to the integrated sensors.

This approach completely transforms closure and screwing processes, as well as all types of assembly processes and, more broadly, any automated pick-rotate-place processes, making them not only more efficient and flexible, but also significantly easier to implement.

Customers can now easily create their own applications, improving productivity and optimising space utilisation, while maintaining high precision and complete process traceability.

Companies that do not upgrade to LinMot linear rotary motors face not only reduced production, but also increased effort and ultimately higher costs.

Delaying this technological evolution means missing the opportunity to adopt more environmentally friendly processes, leading to a decrease in operational efficiency and the ability to adapt to changing market needs, thus putting the long-term sustainability of the company at risk.

We’ve seen cases where customers, fearing change, have missed the opportunity to integrate our products, only to do so after several years of delay, years that have been given to the competition.

In short, the use of LinMot linear rotary motors leads to faster, more flexible and efficient processes, reducing downtime and maintenance time, as well as improving product quality and energy efficiency. This automatically means more satisfied end customers and an improved brand reputation.

However, when we think about the perfect product, it should minimise two aspects and increase two others.

It should minimise the time from start to finish and minimise the effort required.

And the perfect product should also increase the probability of achieving the desired result (we use integrated force/torque and have hundreds of variables available for this). The perfect product should also enable the desired state to be achieved. For customers, this often means increased productivity and flexibility, but then they immediately realise that they can, for example, detect missing parts, have data redundancy, monitor the closing torque characteristic, have full product traceability, predictive maintenance and much more.

As a result, customers often find that they can exceed their original goals, resulting in more satisfied end users and an improved reputation for the machine builder’s brand.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information