Reliable and flexible: Linear motors in pharma cleanrooms. Linear motors are a particularly good solution for pharmaceutical cleanroom applications. They experience very little abrasive wear, require little lubrication at widely spaced intervals, and are easy to clean. For these and other reasons, they are now the state of the art for the noted Swiss primary packaging producer Hoffmann Neopac AG and an indispensable part of modern pharmaceutical production systems. Direct drive technology also sets the standard for flexibility, quality, availability, and traceability of production processes.

A few kilometers from the Swiss capital of Bern, Oberdiessbach is the home of a hidden champion for the primary packaging industry: Neopac The Tube. When product of the first plastic tubes began there in 1958, hardly anyone suspected that the company would one day supply customers around the world with high-tech products. Today, nearly every consumer in Europe has encountered tubes from Oberdiessbach at some point without being aware of it. After all, the clientele of the packaging specialist includes numerous companies from the pharmaceutical, cosmetics, and dental industries. But companies in food production, chemicals, and technology also understand the value of Neopac’s products. The polyfoil tube in particular, invented back in 1965 and improved continuously since then, is still one of the most favored solutions among these customers when it comes to packaging sensitive products. As the name indicates, this type of type has a characteristic multi-layer construction, with one of the inner layers being made of aluminum. It acts as an integrated barrier layer and prevents oxygen from diffusing into the originally sealed product from the ambient air. This protects sensitive contents and improves product shelf life.

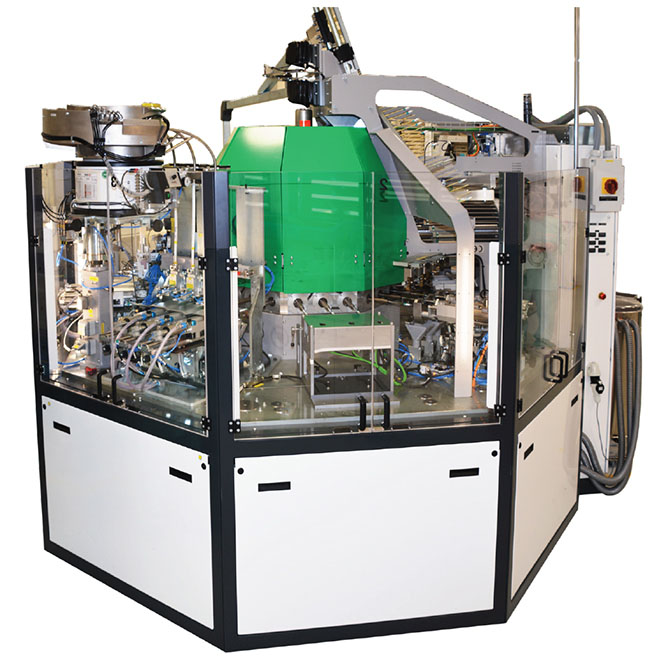

The modular closure machine has space for up to six processing stations. A total of 13 high-performance LinMot linear motors ensure high throughput and flexibility with minimal setup times. (Photo: Rossmann)

200 types of tubes in the standard program

After launching its tube business, Neopac has continuously expanded its production options and capacity and developed a comprehensive assortment of tubes and closures. It includes polyfoil tubes with diameters ranging from 10 to 50 mm. Neopac has also developed a standard program of various head and closure designs. These include heads in the form of cannulas with screw closures, child-proof caps, and tamper-proof seals. This means that users can choose from a total of 200 different variants. Neopac also offers customer-specific solutions. It is also possible to have tubes from Switzerland printed, allowing users to customize packaging solutions to meet their individual needs. Since 2003, Neopac has provided 10 mm diameter polyfoil tubes for pharmaceutical applications as well. A cleanroom and a complete tube production line were built for this purpose. Later, lines for larger tube diameters were ordered for the manufacturing site in Hungary. Production capacity in Oberdiessbach was also expanded again with a cleanroom and an additional production line. The line started production in 2017 and can produce sterile, printed, ready-to-fill polyfoil tubes in 10 mm and 13.5 mm diameters, with lengths ranging from 30 to 61 mm or 45 to 90 mm. Before a tube can leave the cleanroom, it must undergo numerous production and testing steps. Laminate foil Is first welded to form an endless, cylindrical tube and then clad with polyethylene or polypropylene in an extrusion process. The endless tube is then cut to length, a head is injected onto it, and then the body of the tube is printed. The sprue is cut off of the tube at another station, and the closure is screwed or pressed on. A packaging machine handles finishing of the tubes. Before the tubes leave the production room, they are once again manually inspected.

Batches from 10,000 to over a million pieces

“Due to the wide variety of tubes that we provide to our customers, the lines need to be extremely flexible,” explains Petar Djurdjevic, project manager at Neopac.“Short changeover times are important, as the number of small-volume orders for a few thousand tubes is increasing.” A complete product changeover, which includes the tube diameter, must not take longer than three hours, as Neopac specified to the equipment manufacturer in the customer specification for the line. At the same time, the line needs to be capable of handling batches of several million tubes in a few days. Without the use of high-performance linear motors in the closure machine, these targets would never be reached.

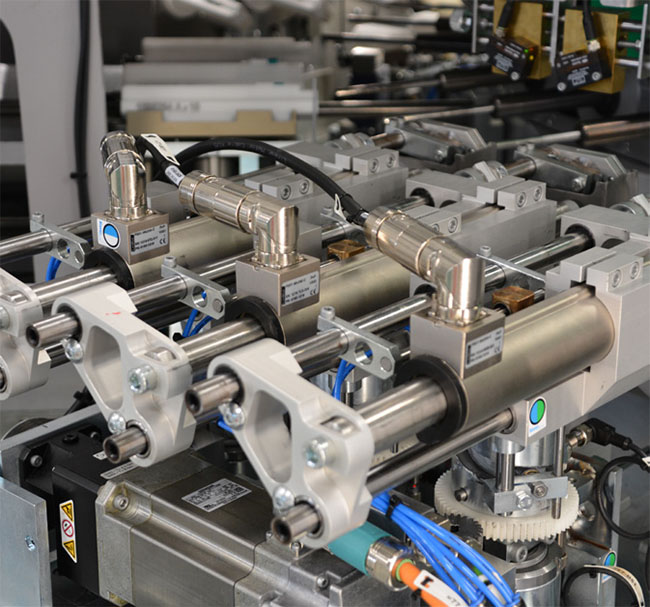

Very little abrasive wear and low maintenance: linear motors and guides from LinMot are FDA-compliant and can be used in pharmaceutical cleanrooms without any additional enclosures. (Photo: Rossmann)

Finishing 300 tubes per minute

With a footprint of about 3 x 3 meters, the modular closure machine installed at Neopac has room for up to six different processing stations arranged around a rotating carousel. The tubes are transported to the closure machine on chain pins and enter a vacuum drum. From there, an attached transfer station places them on rotating vacuum mandrels on the outer circle of the carousels, which then transport the tubes through the machine and rotate them as needed. In the first processing station, the sprue is cut off and the closure is added to the tube in rotating or pressing processed in additional stations. Finally the tubes are stripped off of the vacuum mandrels and transferred out in an unloading station. The entire process is monitored by numerous sensors and industrial smart cameras. Three tubes are processed simultaneously in the stations, at a cycle time of 0.6 seconds, using LinMot linear motors. This corresponds to a maximum output of the closure machine of 300 tubes per minute.

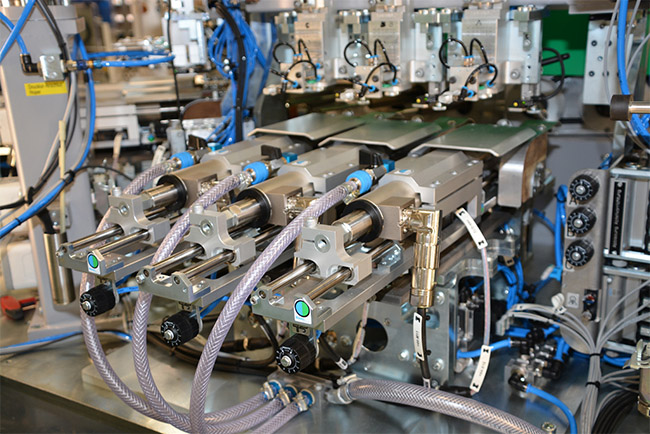

More than positioning: LinMot linear motors can be driven with position or force control. This means that they can also be used for impact processes. In the tube finishing machine, this property is used in the closure station for press-on closures. (Photo: Rossmann)

Flexible, powerful, and fast with direct drive technology

A total of 13 LinMot linear motors, with model PS01-48x240F-C stators, perform positioning and pressing tasks in the stations of the latest generation of machines. With a special motor winding, the stator is able to produce a maximum force of up to 572 N, with a nominal force of 240 N. The maximum stroke is 1,830 mm, at a maximum travel speed of 2.9 m/s. Dynamic, powerful, rapid motions can be produced by these LinMot motors. Series C1150 controllers actuate the axes in the closure machine and communicate with the machine controller via ProfiNet. “One of the greatest benefits of linear motors, in our opinion, is that the motion and force sequences can be freely programmed and monitored,” says Petar Djurdjevic. “Thanks to this flexibility, we can design the stroke motion of the linear motor however we like, and adapt it flexibly to the product requirements, so that the mechanical setup of the motor can remain untouched during a product changeover.” Only the appropriate parameters for travel paths and stop positions need to be entered at the machine interface, according to the product data sheet, or a preprogrammed recipe can be loaded. “We can define specific tolerance ranges for the parameters as well. If they are exceeded or never reached, there is an error message and we reject the affected tubes. The motors help us to ensure quality and traceability,” adds Petar Djurdjevic. Because the motors can be operated with position or force controls, it was also possible to use the same model of linear motor in both the screw-on station for positioning the screw closures and the presson station for pressing on closures. For the manufacturer, and for Neopac, this means fewer spare parts to store and keep track of.

Compact model C1150 controllers are available with all standard industry interfaces. The latest generation communicates with the machine controller via ProfiNet and actuates the 13 linear motors in the closure machine at Neopac. (Photo: Rossmann)

Suitable for cleanroom applications

Another critical factor for the production of tubes in the cleanroom: unlike linear motions produced by ballscrew drives or a combination of servomotors and timing belts, linear motors produce practically zero abrasive wear. LinMot linear motors and the linear guides that support them are FDA-compliant without additional enclosures, and are very low maintenance as well. “We clean and check the motors and guides every four weeks,” adds Petar Djurdjevic. “There is practically never a need to lubricate anything, and if there is, it is in minute quantities.” Another benefit for system operators like Neopac is the high availability of direct drive technology from Switzerland. “Since the start of production on the first cleanroom line in 2003, which also had LinMot linear motors installed in it, we have not had any significant loss of production or problems with the LinMot products. We are completely satisfied.” This summarizes years of experience with the use and application of linear motor technology.

Petar Djurdjevic (right), project manager and designer at Neopac The Tube, speaks with LinMot sales manager for Switzerland, Michael Glauner, about the advantages of using linear motor technology in cleanroom applications. (Photo: Rossmann)

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information