In the life sciences sector, the design of machinery for product processing is critical.

The use of specialised, high quality equipment is essential to ensure precision, reliability and safety. These machines must meet stringent standards as even the smallest error can affect results and product safety. The use of state-of-the-art components, durable materials and advanced technologies ensures excellent and long-lasting performance. Investing in quality not only increases production efficiency, but also enhances the company’s reputation and creates trust and satisfaction in the increasingly demanding life science market.

LinMot’s linear actuators play a crucial role in this. Their high accuracy and repeatability make them ideal for applications that require precise motion, which is particularly important in the life sciences industry. LinMot linear actuators also offer exceptional reliability, ensuring a smooth production process without unplanned downtime.

It should be noted that LinMot linear actuators are also available in stainless steel. This makes them particularly suitable for sterile environments, as they are easy to clean and disinfect and therefore meet the highest hygiene standards. This feature is of particular importance in the life sciences industry, where cleanliness and hygiene are of the highest priority.

An overview of all LinMot products is available on this page:

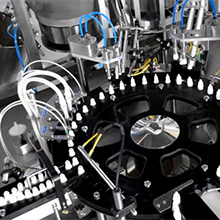

As a leader in the MENA area for pharmaceutical machines and production lines, AFAQ puts a lot of effort in comparing and selecting state-of-art systems to be used in its Ophthalmic Drop Filling and Closing Machine (DropFill-SC) series.

With over 6 billion products processed every year, and the cutting-edge linear drive technology from LinMot, the unique coding machines from Hicof are the tip of the spear in the fight against counterfeiting.

Multiformat filling and sealing system at Zellwag Pharmtech AG with precision linear rotary motors from LinMot.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information