Of all the resources on which modern manufacturing depends, energy is arguably one of the most pivotal. Energy efficiency and thus carbon footprint are an important indicator of companies’ contribution to sustainability and climate protection. Indeed, the manufacturing industry is increasingly looking for sustainably made products and considering this issue as an essential component in their purchasing decisions. Energy is also a resource that has long been taken for granted, but rising prices and concerns about greenhouse gas emissions are causing operators to critically evaluate how to produce more with fewer resources. The key to achieving this is to switch to LinMot and eliminate power losses in energy-intensive processes of factory automation such as pneumatic applications (compressed air).

Companies use pneumatic actuators because of the somewhat lower investment cost. Compressed air, however, is one of the most expensive energy media, because compressors can convert only a small portion of the input energy into useful power. The great majority is dissipated as heat loss. On the other hand, LinMot relies on direct-drive brushless tubular linear motors with extremely high efficiency. In addition, and in contrast to pneumatics, the linear motor not only does not draw energy beyond what is needed but can also convert energy during braking and store it for the next cycle. Due to the high operating costs of pneumatic cylinders, linear motors prove to be a cost-efficient alternative where the higher investment cost can be paid back in a matter of weeks. It should be no wonder, then, that more and more companies are attempting to eliminate compressed air from their factories.

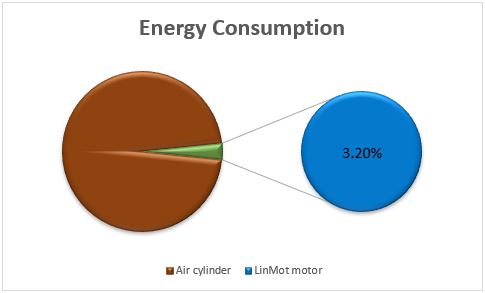

Various studies show that linear motors are preferred to optimized compressed air systems, both in terms of economic and ecological savings. US cotton, a manufacturer of cotton swabs, decided to replace their pneumatic cylinders with LinMot linear motors and measure if the energy savings do indeed justify the price of the LinMot motors. The linear motor did consume only 3.2% of the energy of the pneumatic cylinder equipped in the machine. Furthermore, the better control also meant a 35% increase in machine speed, and the absence of adjustment or replacement of linear motors means trouble-free operation for many years.

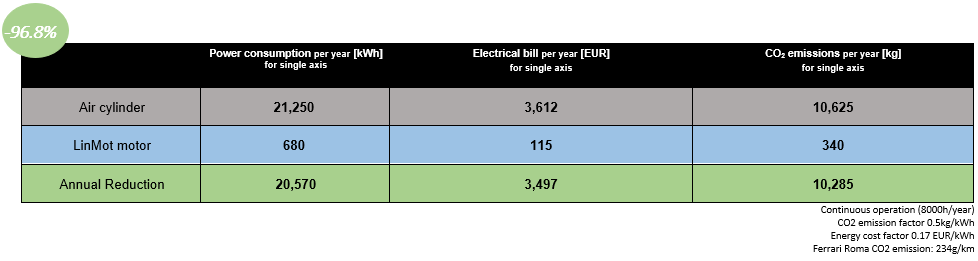

If we were to calculate the annual electricity bill and CO2 emissions of the previous example, in which the total moving distance per cycle is 800mm and the total cycle time is 900ms, we would get the following results:

| For a production line using 100 pneumatic cylinders, this will result in annual savings of 349,700 EUR in electricity expenses alone. The CO2 reduction is enough to drive a Ferrari Roma 110 times around the world. |  |

In addition to achieving significant energy savings, further cost reductions are also achieved by the lack of mechanical transmission components (gearboxes, timing belts, pulleys, cams, lead screws, etc.), hence allowing for a cleaner mechanical assembly, fewer parts, and smoother, quieter operation. The total cost of ownership (TCO) is also minimized by the reduced logistics and installation costs due to a minimal number of standard components. Production costs are also lower due to the higher throughput, more reliable motions, improved mean time between failures (MTBF), drastically lower maintenance and change over costs.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information