Separating and routing delicate fish portions to various product channels at high speed is a challenging job. Valka, an Icelandic hightech company that designs and builds progressive systems for fish processors, is equipping its grading and sorting machinery with LinMot stainless steel motors for the speed and accuracy demanded in a difficult washdown environment.

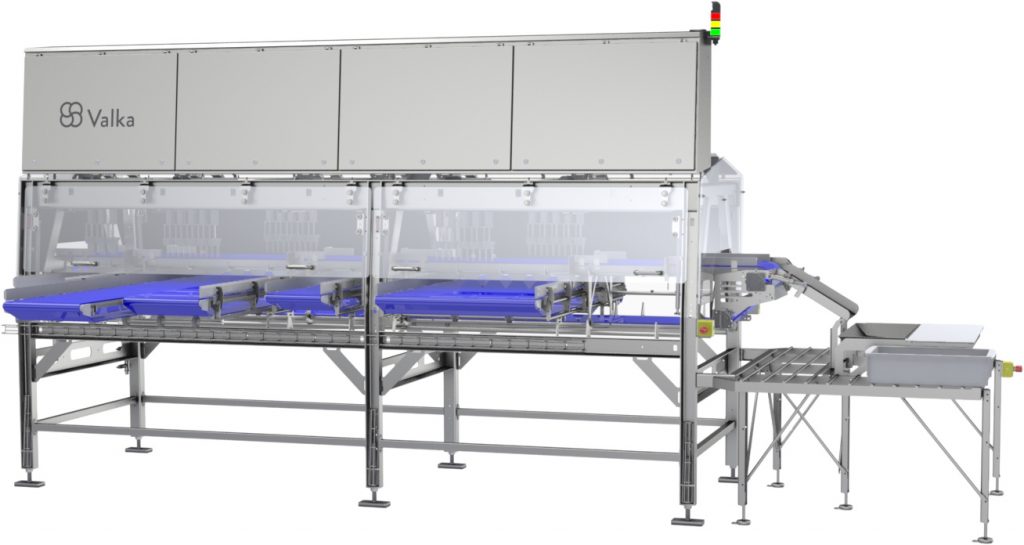

Valka’s processing systems include several automated units grading, cutting, portioning and batching fish products. A key part of the system is a portion grader that automatically sorts pieces into various product channels and streams. “When designing this system, several criteria had to be considered”, says Ivar Meyvantsson Product development manager at Valka. “First of all accuracy, secondly speed and thirdly our customers work in a washdown environment. LinMot’s stainless steel linear motors provide an excellent combination of benefits in all of the categories.”

Scheme Portion sorter from Valka

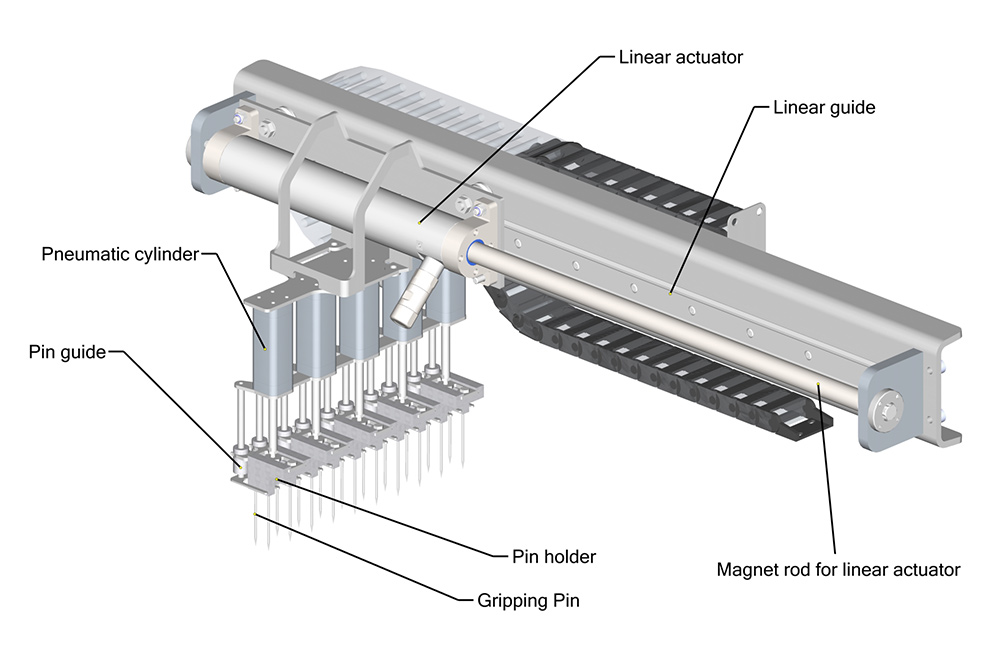

Accurate sorting with no margin for error

Sorting into production streams is typically preceded by automated cutting of fish fillets into pre-defined pieces. As the pieces enter the portion grader, they lie tight up against each other. The spatial precision of the linear motion arm has a significant impact on the ability to accurately pick a specific piece from the conveyor. “With LinMot’s excellent position repeatability, we can be certain that we pick the right pieces. While pneumatic actuators have several benefits for food processing environments and can be fast, they do not offer positional accuracy Error in the location can lead to pieces being missed or different pieces being dragged along into the wrong product stream. In addition, a high degree of motion control helps minimize damage to the raw material.” Ivar continues.

Stainless Steel Motors from LinMot

Speed is critical and compactness important

The production lines utilize highspeed conveyor belts. The speed of the linear actuator pulling the pieces from the conveyor correlates directly with the overall production capacity of the manufacturing line. Highspeed actuators enable the product to be carried at a higher speed through the machine without risk of missing pieces. If pieces are missed, they run to the end of the line, where an operator must manually sort pieces into the correct product streams, thereby increasing operating cost significantly. “While ball-screw systems provide high accuracy, they tend to be a lot slower than LinMot’s actuators and also take up a lot more room”, Ivar continues.

Another point to consider is that the production facility real estate is valuable. The more production equipment that can be fitted in the available space, the higher the capacity for production. Compact actuators help keep the footprint of our system at a minimum.

Linmot motors Portion Grader

Washdown areas in fish processing are among the most difficult

Last but not least, cleanliness is the critical consideration for fish processing. All the components in the Valka systems must both enable easy cleaning and tolerate aggressive pressure washing and cleaning solutions. Simple geometries and robust housing help on both fronts. “Regarding cleaning, other linear actuator designs tend to have crevices that are hard to clean, and many are not available with IP-69k rating ensuring protection against high-pressure spray-down.” Says Ivar finally.

Read more about the stainless steel motors

Autor: Ágúst Sigurðarson, Marketing Manager, Valka

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information