The Pharmaceutical sector is considered as one of the most demanding sectors in the industrial field. Machine designers and builders must consider and respect many rules and standards and should mandatorily apply the cGMP (current Good Manufacturing Practices). These rules and guidelines become more restricted when the machine is handling aseptic medicine, such as Ophthalmic Drops.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

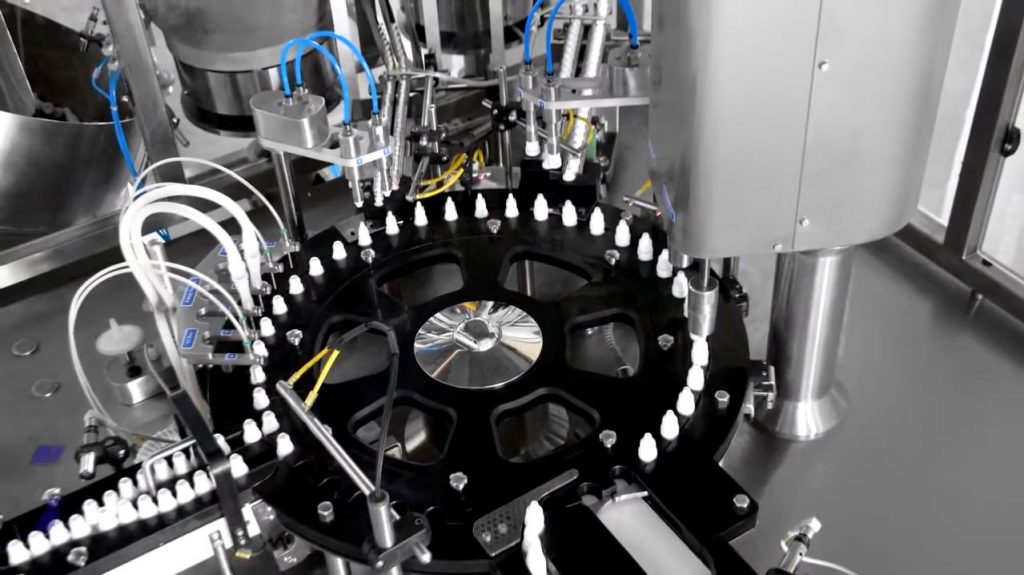

As a leader in the MENA area for pharmaceutical machines and production lines, AFAQ puts a lot of effort in comparing and selecting state-of-art systems to be used in its Ophthalmic Drop Filling and Closing Machine (DropFill-SC) series. The use of LinMot products and systems helped AFAQ provide to its customers many advanced functionalities which allow their machines to strictly respect the international rules and guidelines such as FDA, EMA and cGMP.

First of all, the gentle motion of packaging material is an important point to guaranteeing a stable, reliable filling, and closing. With this we used the driver E1450 series with a third-party provider of rotary servo motor, where, with the help of advanced parametrization available in the Linmot-Talk software, we could work on the edge of low jerk motion profile. This allow AFAQ to provide a stable liquid into the container without any compromise for the motion speed, hence to the machine productivity.

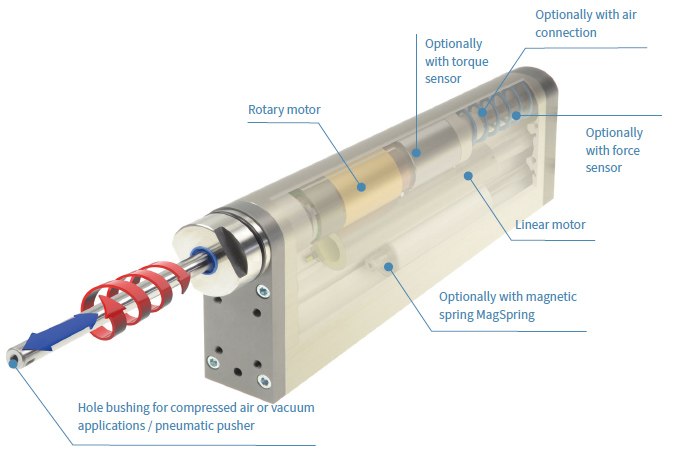

The same challenge should be considered when we design the pick and place robot arm for the stopper and cap insertion. The smooth and fast motion, side-by-side with the easy motion profile building and optimization with only a few teach-in steps, supported our customers to reach a high performance quickly and effectively even with other size of containers. The change from one container size to another, was easy and reliable. The PR01 linear rotary servomotor and C1150 driver family gives AFAQ the flexibility to build this robot arm with few mechanical components (no power transmission, belt and pulley are needed), and with low maintenance needs

Finally, with the new challenge of containers closing, a tight torque should be reached precisely to prevent the contamination of the drop and solution into the container. The Linear/Rotary servomotor combination from LinMot PR02 and the C1250 driver family, could give us the needed flexibility and accurate torque control in accordance to the torque setpoint provided by the operator through the 10” HMI. The PR02 series of linear rotary servo motors provides us the desired rotary and linear motion – needed in tighten heads- into a very small package and integrated with a torque sensor (and force sensors as an option). All these wonderful components were the key factors in the success of AFAQ DropFill-SC series.

ProfiNet fieldbus

All the above complicated functions and systems are controlled and managed through ProfiNet fieldbus to provide a central control system, also, it helps us to provide our customers a high-level monitoring and diagnostic system that gives the profound details about the health of the systems and machine.

As a leader in the field of machine building AFAQ has the higher commitment to its customers. Thus, great effort is provided to choose a reliable partner like LinMot that allows us to integrate their high-level systems to our machines, which constitutes a sure guaranty of the customer’s satisfaction and success.

More about the products from LinMot

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information