We spoke to Reto Brumann, LinMot‘s Product Manager for Robotics and the driving force behind LinMot Pilot, to find out more about this smart solution‘s idea, functions and potential. Read on for an interview about skills shortages, user-friendly technology, and the courage to simplify.

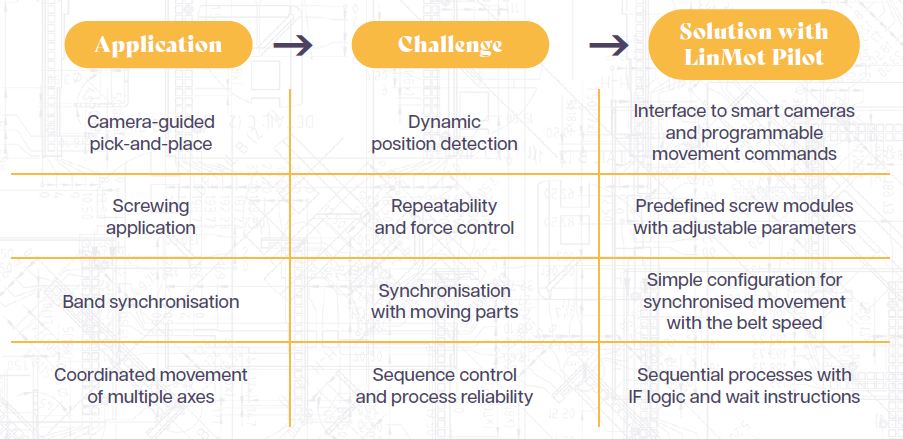

LinMot Pilot is a user-friendly, web-based platform for configuring and controlling multiaxis LinMot systems, eliminating the need for PLCs or in-depth programming knowledge. Rather than using complex code, LinMot Pilot relies on customisable commands and intuitive widgets. This enables complex processes such as screwing, conveyor synchronisation and pick-and-place with camera connection to be implemented safely and efficiently.

The increasing demand for simple, intuitive solutions, driven by a shortage of skilled workers and ever-more complex requirements, inspired us. Following on from our flat robots and grippers, offering a suitable control platform was the next logical step.

Thanks to our expertise gained from numerous applications, our products should be usable without any programming hurdles. LinMot Pilot enables even the most demanding applications to be implemented quickly and easily.

LinMot Pilot is not just a programming interface; it is a complete HMI. The customisable user interface is processreliable and is already in productive use today — it is a robust control solution, not a testing ground.

Sequential programmes can be created in just a few clicks. These programmes can include IF queries, waiting times, jump labels, variables and movement commands. There are also function packages available for specific processes, such as screwing or smart camera integration.

All movement commands can be selected, configured and sequenced via a drop-down menu. Positions can be caught using a teach button or manually. If desired, variables can also be used without traditional code.

For anyone who wants to automate, including system integrators, the automation or development departments of manufacturing companies, test laboratories, and creators of semi-automated workstations. It is ideal for small to medium-sized businesses that rely on flexible, intuitive solutions.

Absolutely. The entire configuration process is carried out via the web interface, with no need for additional software. Thanks to guided input, even complex tasks can be solved without the need for PLC experts, and typical programming errors are avoided.

We are already working on new feature packages for beltfed processes, smart camera applications, screwdriving solutions, and advanced process monitoring. LinMot Pilot evolves to meet the changing needs of our customers.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information