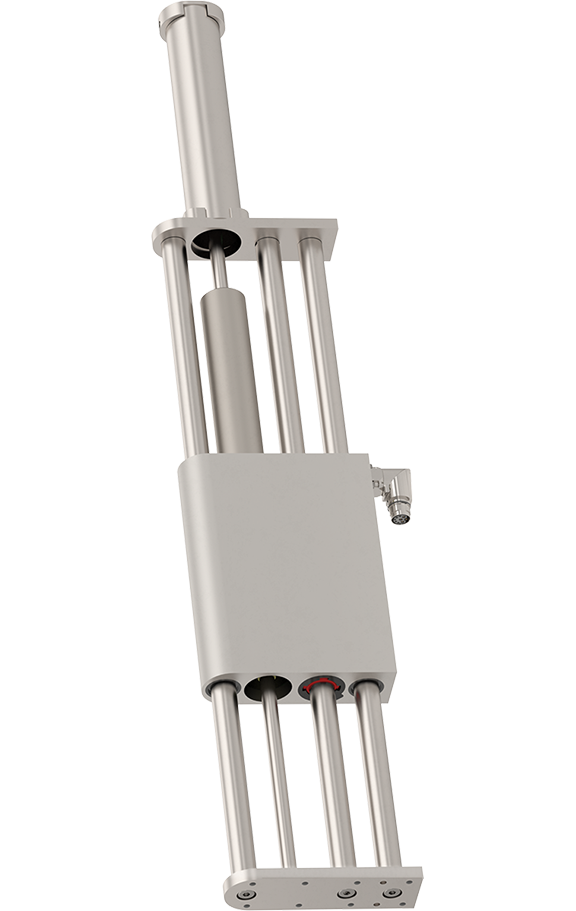

Designed specifically for vertical applications, the DM03 series linear modules offer a large stroke range in an extremely slim housing. This means that DM03 linear modules can be placed close together to save space. The slim housing incorporates a new, more powerful generation of MagSpring® for vertical load compensation and can be supplemented with a high-resolution position sensor in the module or a force sensor on the front.

The ingenious mechanical design of the DM0x linear module family prevents high contact forces between the motor and slider, resulting in a very long service life with minimal motor maintenance. In addition, these linear modules already have an integrated, weight-optimized guide system for absorbing lateral forces and for easy mounting of the load mass.

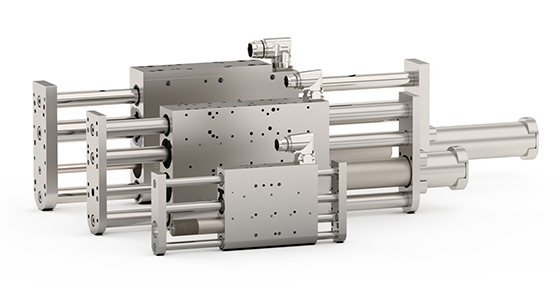

A total of five different sizes are available to the user. The motor range from 23x80F-HP to 48x240F-HP offers maximum forces from 67 N to 1020 N. These highly dynamic linear modules leave nothing to be desired in terms of dynamics and easily achieve accelerations of 50 m/s^2 and speeds of up to 5 m/s.

Installed parallel to the linear motor, the MagSpring acts as an intelligent load compensator for the weight force. With the new generation of MagSprings, the weight compensation can be selected in steps from 11 N to a maximum of 170 N. Thanks to the fine gradation of the MagSpring, applications can be designed in such a way that the position of the linear motor does not automatically change in the event of a fault, or that a reference position is automatically reached when the motor is switched off.

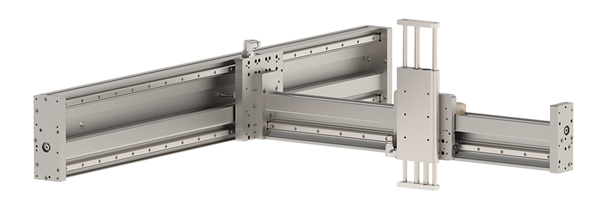

The DM03 linear modules offer a wide range of maximum forces and stroke lengths. This variety of forces and sizes, together with their modularity, allows them to be combined with all other LinMot modules. The combinations allow different structures such as semi-gantry, gantry and pick-and-place (YZ) to be realized. Advantages of semi-gantry constructions:

The video shows a DM03 linear module with a stroke of 695 mm. The long stroke, integrated load compensation and dynamics of the linear motor make this linear module particularly suitable for vertical applications with long strokes, short process times and the need for low energy costs.

Application example: In many applications, such as labeling, packages of different sizes are processed on a conveyor belt. Depending on the size of the package, different strokes have to be covered and the labeling process has to be carried out as quickly as possible. The DM03 linear module demonstrates its outstanding dynamics in such high-speed processes, covering a stroke of 695 mm in just 300 ms. Thanks to the integrated load compensation, the module also ‘floats’ weightlessly, allowing the linear motor to use its full dynamics for the actual application.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

To demonstrate the potential savings, the application described above was set up in which the DM03 linear module covers a stroke of 695 mm in approximately 300 ms. The annual energy consumption of this application is 405 kWh. By comparison, a 32 mm pneumatic cylinder would consume 12,000 kWh. This represents a 30-fold reduction in energy consumption and a saving of €2,900 per module per year.

How do you make labeling processes for packages of different sizes as fast and safe as possible? And, above all, how can this be achieved in vertical applications where the weight of the axis and the load are constantly acting on the process? Our article in LINEAR gives you the answer.

We will be happy to answer any questions you may have.

Please contact us using the following form or call us at:

Tel: 262-743-2555

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information