Dynamics in the filling and sealing machine industry. Since 2002 Zellwag AG has put their trust in linear motors when building their fully automated filling and sealing machines for pharmaceutical and cosmetic products. They make machinery especially productive, flexible, and economical. This has enabled the company to place its machines in many applications where products are filled and sealed semiautomatically or fully automatically. The systems builder has now raised the top end of its portfolio, adding the Z-110g modular machine platform for large batches. Once again it has taken advantage of the benefits of dynamic and compact linear motors from LinMot.

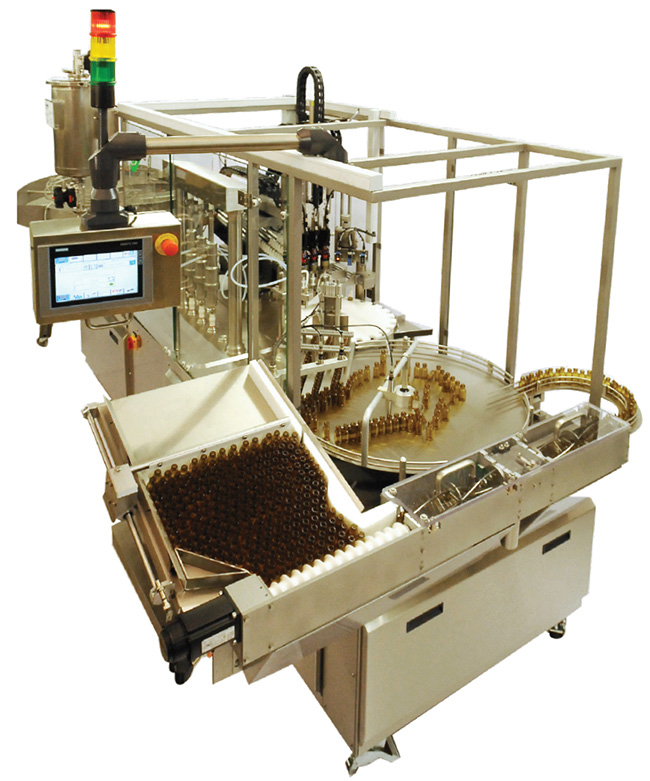

Linear machine Z-201 S(Photo: Zellwag)

«When we decided in 2002 to replace pneumatic drives with linear motors in critical locations on our Z-201 filling and sealing machine platform, there were substantial reasons,» explains the managing director of Zellwag AG. The transition to direct drives came at time when only very innovative companies had placed their trust in the new drive technology. «Only linear motors could enable us to increase the flexibility and performance of the machines the way that we and our users envisioned.»“ The decisive factors here are the higher travel speed compared to pneumatic cylinders, the higher precision and the better possibilities for controlling and synchronizing the linear motors. «Compressed air cylinders also have the disadvantage that they behave differently depending on the ambient temperature, and therefore are not really capable of providing the necessary repeatability». Pneumatic cylinders also need maintenance, while linear motors are in fact maintenance-free.

Product changeover at the push of a button

An even greater influence on productivity, especially for small lots, is the ability to use software to change the control parameters of direct electrical drives. Zellwag AG has put this to use in the concept of its machines for processing various types of and sizes of packages. A product changeover can be made at the push of a button, with no configuration or adjustments necessary. For several years, however, another feature of linear motors has inexorably moved into users› field of view: the exceptional energy efficiency of linear motors. «Pneumatic actuators have high compressed air consumption, extremely high for screwdriving processes,» the managing director of Zellwag asserts. Because it takes a lot of energy to produce compressed air, of which only a small amount «arrives» at the actuator in the form of work output due to the poor efficiency of the compressed air system, the use of electric drives with an efficiency of over 90 presents the user with a way to lower operating costs and to improve the ecological balance.

The new Z-110 modular machine platform from Zellwag is designed for large batches. It enables filling and sealing solutions to be implemented for filling liquid and powdered pharmaceutical and cosmetic products. With the use of linear motors in place of pneumatic cylinders, it is especially flexible and productive.(Photo: Zellwag)

The advantages of electric linear actuators compared to pneumatic cylinders

Zellwag selects LinMot again

A recent internal evaluation of available technologies prior to the launch of the new Z-110 machine platform confirmed again, as expected, the technical, economic, and ecological advantages of linear motors from LinMot. This and over 100 Z-201 systems sold, with around 500 installed linear axes with no significant breakdowns have persuaded the responsible parties at Zellwag AG to use linear motors from LinMot to implement the critical processing steps on the new machine platform as well. These include filling (moving metering units), gripping and placing the plug and screw cap, and centering the riser tube for cases where pump spray heads are used as a closure. The result is the Z-110, characterized by a thoroughly modular structure and extremely flexible in application due to its direct drives and numerous options. It is designed for filling liquids of varying viscosity, including powders, and can process ampoules and glass bottles with diameters between 15 and 40 mm and heights from 24 to 100 mm. Depending on the equipment level, the system can process up to 7,200 units per hour.

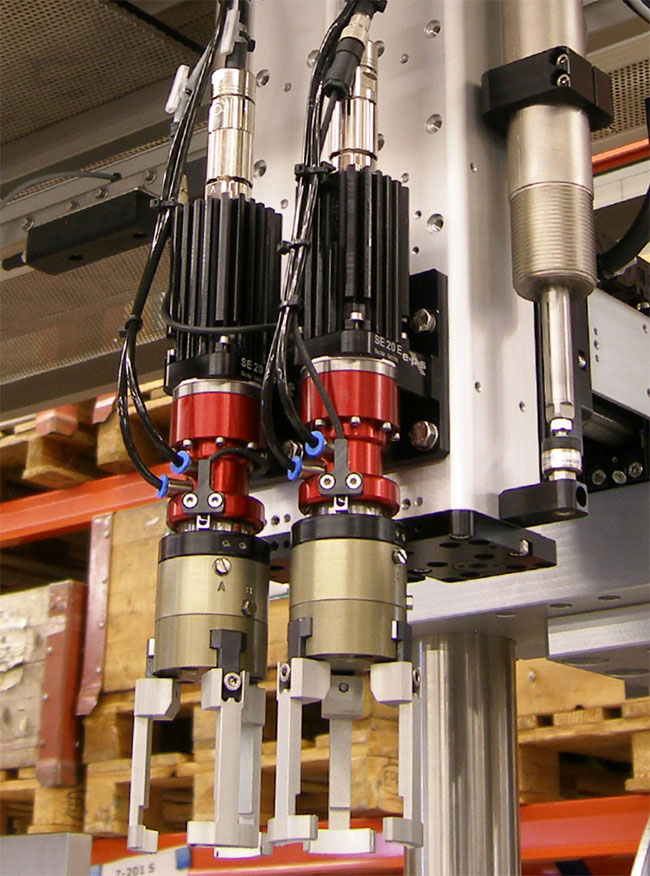

Linear axis from e-p-s with LinMot linear motor and additional rotary axis for gripping, placing, and threading on pump spray heads or rotary caps. (Photo: Zellwag)

Powerful and compact: linear axes with LinMot drives

The machine nevertheless has a footprint of just 3350 x 2280 mm, despite the fact that Zellwag has not compromised on ergonomics or accessibility. The good accessibility is largely due to the very compact form factor of LinMot solutions, which has enabled e-p-s (the supplier of the screwdriving axes for the Z-110 and systems integrator for LinMot in Germany) to pack high performance into minimal installationspace. Several model EDM30-300 EL linear axes have been installed that are only 58 mm wide but are rated for 40 Nm of torque in the X and Y directions and 30 Nm in the Z direction at the gripper flange. They generate a constant force of over 250 N over the entire 300 mm stroke (when supplied by a 15 A controller). Because the machine can contain up to 16 direct drives, with up to four independently transportable pump stations and a maximum of four pick & place units with electric servomotors as rotary axes (as well as additional options), the compact form factor of the linear axes was particularly important to the design of the Z-110.

«Users require portable machines, so we integrated the electrical enclosure directly in the frame of the machine,» adds the managing director of Zellwag. «This meant that we had to be particularly frugal with space. »Here again, LinMot had the right solution available. The servocontrollers from the company›s E1130 series are just 40 mm wide, 250 mm high, and 180 mm deep, although the HC variant can provide a peak current of 15 A. Ever since, these powerful controllers have handled both the actuation of the linear motors and the rotary servomotors in the Z-110 and communicate with the machine controller via the optional Profibus interface (DP).

The linear and servomotors on the Z-110 are controlled by particularly compact servocontrollers from LinMot, with a PROFIBUS interface (DP) and 15A maximum current. (Photo: Zellwag)

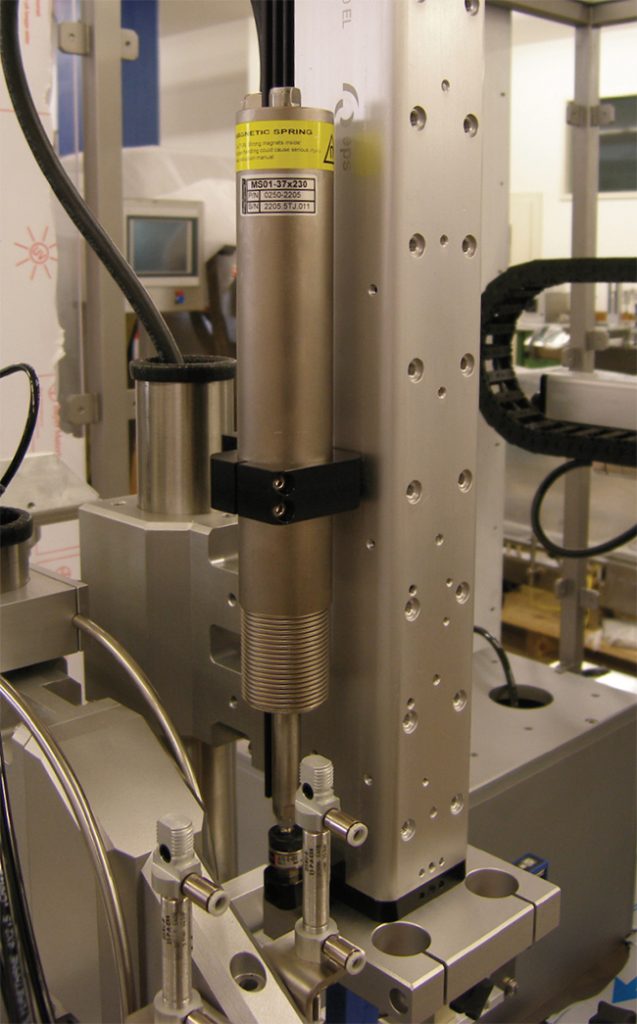

Magnetic springs relieve linear motors

The linear motor axes installed vertically in the Z-110 are mechanically supported by MagSprings. These «magnetic springs» from LinMot provide a constant force over their entire stroke that is independent of position, speed, or orientation and thus compensates for the weight of the linear axis. The motor only has to provide the dynamic forces, so it can react faster and be smaller in size. If the MagSpring force is selected to be greater than the weight of the load, then the load can be moved to a safe position if the power is interrupted. MagSprings also require no maintenance, are not sensitive to wear, and take up only a little space. «The overall package that LinMot and e-p-s provide is outstanding,» concludes the managing director. «There have been a lot of competitors that have wanted to get their foot in the door with us. As things progressed, however, it became clear that they were ultimately unable or unwilling to complete the job. This confirms our conviction that selecting e-p-s and LinMot was and is the best decision.»

A “magnetic spring” compensates for the weight of the vertical axes and relieves the linear motor so that it can react more precisely and dynamically. It reduces power consumption at the same time. (Photo: Zellwag)

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information