Transform your manufacturing process with linear motor solutions from LinMot® to increase productivity and minimize downtime!

• Innovative motors perform highly dynamic linear and linear-rotary motions.

• Cutting-edge motor technology is proven to reduce maintenance,

• Increase speed and have a longer service life – up to several billion cycles in real applications.

• There are no belts, screws, cams, or gears that will wear out over time.

• Each motor features a direct drive system and provides the utmost reliability and flexibility.

• Our motors and drives are designed for seamless integration into any overlaid control system.

This makes our products the perfect fit for rugged industrial environments, including those within production and automation applications. Incorporate them into your existing operations—along with our MagSprings and DC Servo Drives—to create the optimal drive system.

Thousands of customers have streamlined their product cycles using LinMot motor technology. Discover how we can revolutionize your manufacturing process together. Our professionals will recommend tailored solutions for your specific applications.

This application note shows how a LinMot CM interface (EtherNet/IP interface, e.g., C1250-CM-XC-xS drive) can be integrated and setup in a Rockwell Automation environment as a motion axis for coordinated motions.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

Get a complete tutorial on how you the integration of LinMot Motors work on Rockwell Automation CIP Sync on our YouTube Channel:

How-to Integrate LinMot drives with LinMot EtherNet/IP CIP Sync interface in a Rockwell Automation environment as motion axis.

Download the “How-To”-Guide (PDF)

LinMot Servo Drive are compact positioning controls with one or more power units for controlling the motors and an intelligent control unit with integrated position control. The control unit takes over all drive-related control and monitoring functions.

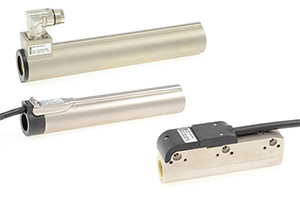

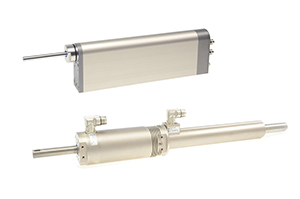

LinMot motors are electromagnetic direct drives in tubular form. The linear movement is generated entirely electrically and wear-free without the use of mechanical gears, spindles or belts.

LinMot linear guides are compact guide units for linear motors. The guides are used to support the load, to absorb external forces, handle torsional and bending moments, and at the same time as an anti-rotation device.

LinMot’s linear rotary motors are characterized by excellent flexibility, dynamics and speed. They can be used to realize both linear and rotary movements.

MagSpring products are best described by the term “magnetic spring”. However, the term spring is to be understood in the sense that MagSpring components generate a constant force over the entire working range, whereas a typical characteristic curve of a mechanical spring shows a path-dependent increase in force.

LinMot’s range of accessories, which is matched to the linear motors, allows the quick and uncomplicated realization and commissioning of a wide variety of tasks.

Filling and closure processes can be implemented dynamically and flexibly with linear rotary direct motors. That’s why noted packaging machine manufacturer OPTIMA uses them in the closure units for its monoblock and free-standing machines. Another important reason is that the motors directly provide data on the actual stroke and torque values generated for ongoing quality assurance or subsequent process analysis. This type of drive supports modern Industry 4.0 concepts right down the line.

Read the whole application report

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information