LinMot is a technology partner of Bosch Rexroth AG and is now part of the ctrlX World Partner network for ctrlX AUTOMATION – a platform that sets new standards in industrial automation.

Our highly dynamic linear motors and direct drives can be seamlessly integrated into the open ctrlX architecture and offer maximum flexibility, reliability and efficiency. By combining our mechatronic solutions with ctrlX AUTOMATION, we enable plug-and-play integration, real-time communication and easy scaling.

Our solutions are ideal for demanding industrial environments and support modern I4.0 concepts through intelligent data processing and machine communication.

How to integrate LinMot drives with LinMot EtherCAT interface (DS402 CoE) as synchronous motion axes into the ctrlX AUTOMATION from Bosch Rexroth.

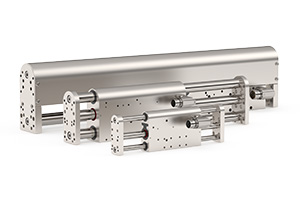

LinMot motors are electromagnetic direct drives in tubular form. The linear movement is generated entirely electrically and wear-free without the use of mechanical gears, spindles or belts.

LinMot linear guides are compact guide units for linear motors. The guides are used to support the load, to absorb external forces, handle torsional and bending moments, and at the same time as an anti-rotation device.

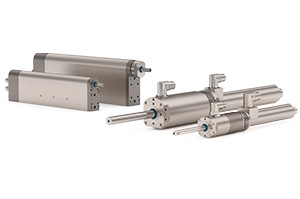

LinMot’s linear rotary motors are characterized by excellent flexibility, dynamics and speed. They can be used to realize both linear and rotary movements.

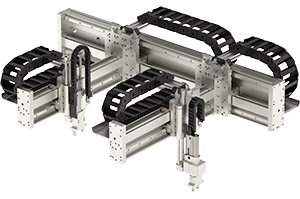

LinMot flat robots and systems offer innovative and easily configurable gantry, semi-gantry and pick-and-place solutions. With the ready-to-use multi-axis systems, even complex industry-specific requirements can be realised quickly and precisely.

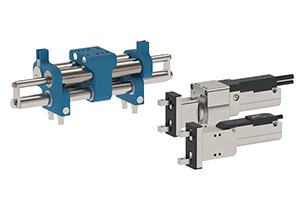

LinMot grippers are highly dynamic solutions for demanding pick-and-place, assembly and screwing tasks. They offer fast closing and opening times, precise finger positioning and accurate force control.

LinMot Servo Drive are compact positioning controls with one or more power units for controlling the motors and an intelligent control unit with integrated position control. The control unit takes over all drive-related control and monitoring functions.

MagSpring products are best described by the term “magnetic spring”. However, the term spring is to be understood in the sense that MagSpring components generate a constant force over the entire working range, whereas a typical characteristic curve of a mechanical spring shows a path-dependent increase in force.

LinMot’s range of accessories, which is matched to the linear motors, allows the quick and uncomplicated realization and commissioning of a wide variety of tasks.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information