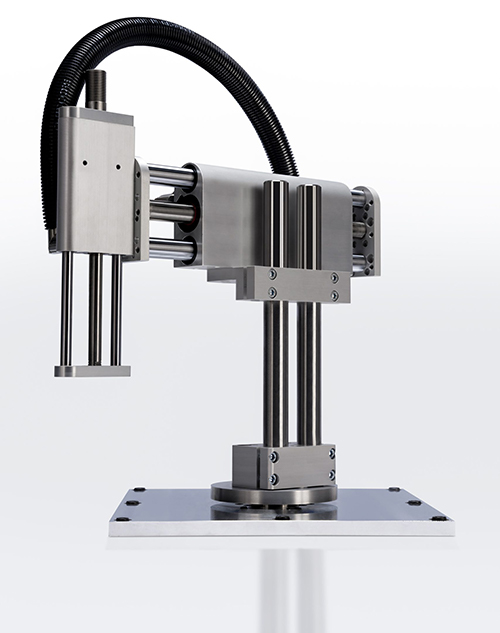

Juggling labor gaps, sustainability needs and production demands can be a challenging task. When your operations require you to handle parts and materials, the DM pick and place robot with rotary motion is an ideal solution for overcoming these challenges. Easily pick up objects and place or press them into various types of packaging or assemblies. All without the robot becoming fatigued or suffering repetitive motion injuries.

Continue reading to explore 4 ways the LinMot DM pick and place robot with rotary motion simplifies parts and material handling.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

The DM Pick and Place robot comes equipped with LinMot Designer simulation software. This software is available online at any time and ensures the correct selection and design of the linear modules. Further enhancing ease of use, the plug and play technology available within the robot’s guided motor simplifies drive commissioning. This technology enables the motor configuration parameters to be automatically read into the servo drive.

Several options are available with the DM pick and place to complement your application’s needs.

Read about the options more in depth

LinMot products are designed to be a sustainable solution to your linear motion needs. The DM pick and place robot with rotary motion is a great choice for those who need to comply with EPP policies and are trying to meet ESG goals.

Benefits that enhance sustainability include:

The DM pick and place robot with rotary motion minimizes Total Cost of Ownership (TCO) by reducing logistics, installation costs and maintenance. This is possible thanks to the minimal number of standard components.

Simplify your parts and material handling with LinMot’s sustainable DM pick and place robot with rotary motion.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information