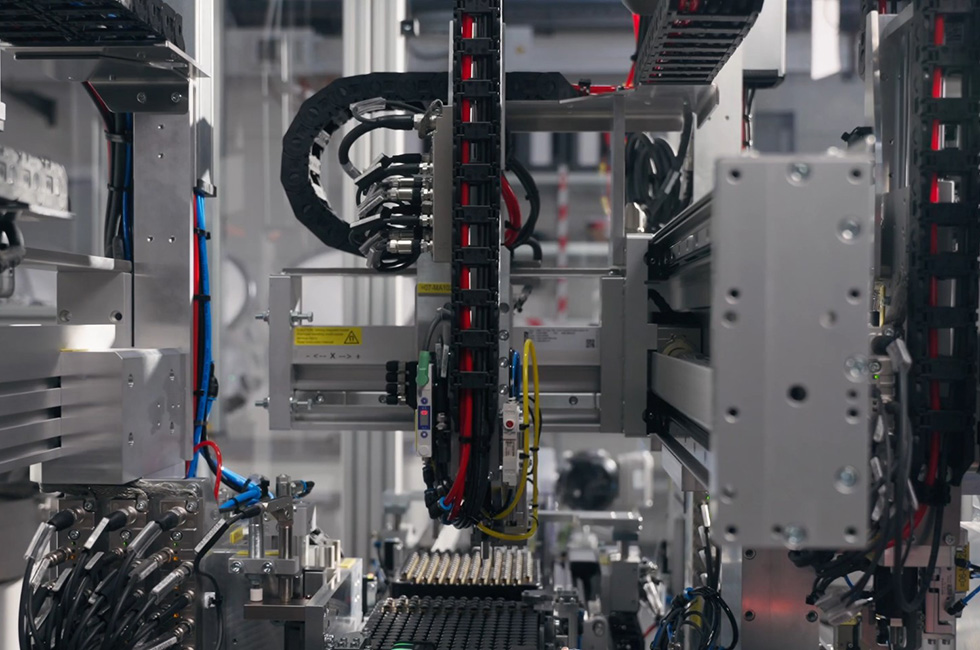

The demands on modern automation solutions are continuously increasing: ever more compact machine layouts, higher cycle rates, and maximum process reliability meet a growing variety of applications. With the new Flat Robots and Systems, LinMot provides the perfect answer — a consistently modular system concept that enables applicationspecific multi-axis systems to be implemented quickly, space-savingly, and precisely tailored to each process. From single axes to scalable complete systems, our Flat Robots are as versatile as the requirements of tomorrow.

The global market for linear drives is currently experiencing remarkable growth. In particular, the demand for electric linear drives has increased significantly in recent years — a trend confirmed by numerous studies and market analyses. The reasons for this dynamic growth are manifold: higher Energy efficiency, improved controllability, easy Integration into digital systems, and not least, greater sustainability compared to pneumatic solutions. But are the available solutions really as comprehensive as they appear at first glance?

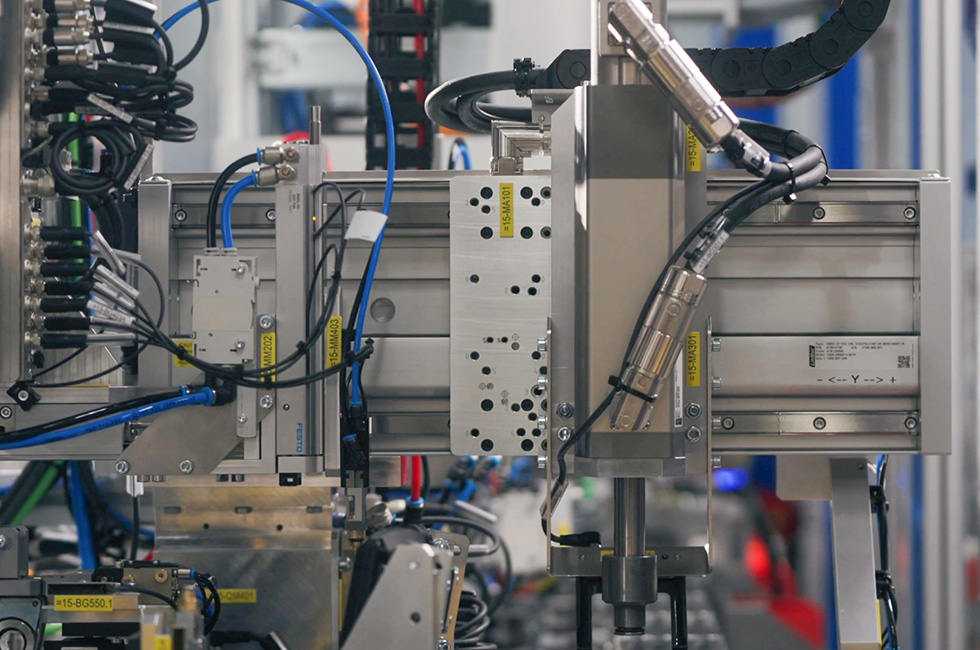

As impressive as the market figures may be, in practice many drive systems quickly reach their limits. A survey by the PW Consulting Automotive & Machinery Research Center shows that 52% of integrators complain about the lack of modularly integrated guides or sensors — and the resulting high degree of customization required. And not without reason: the absence of standardized mounting options alone makes numerous customer-specific components necessary. As the Research Center further reports, this leads to setup costs in production lines – for example in medical device manufacturing – of up to USD 1,800 per axis. This is precisely where LinMot comes in: with solutions that, thanks to the standardized modular design of the drive elements, significantly reduce the effort required by machine builders.

“Of course, machine builders can accept the high customization effort and associated Costs and develop their own solutions for simple handling Tasks. But in practice, the first hurdle soon becomes apparent.”

Andreas Nowak

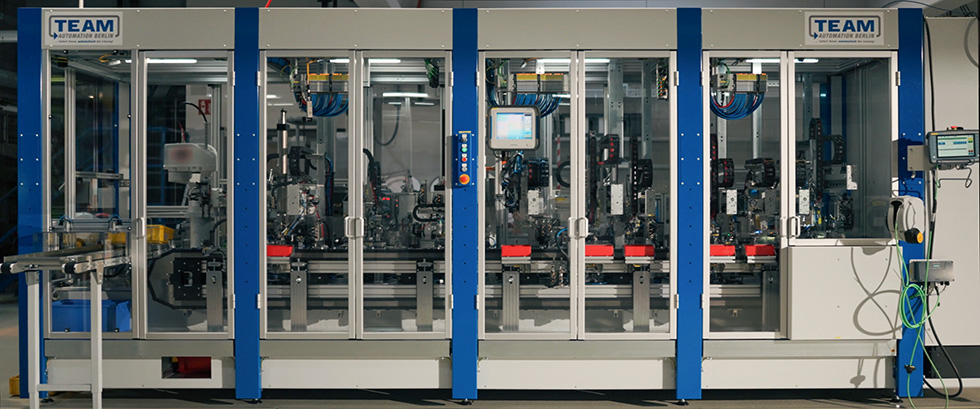

Managing Director at TEAM Automation Berlin

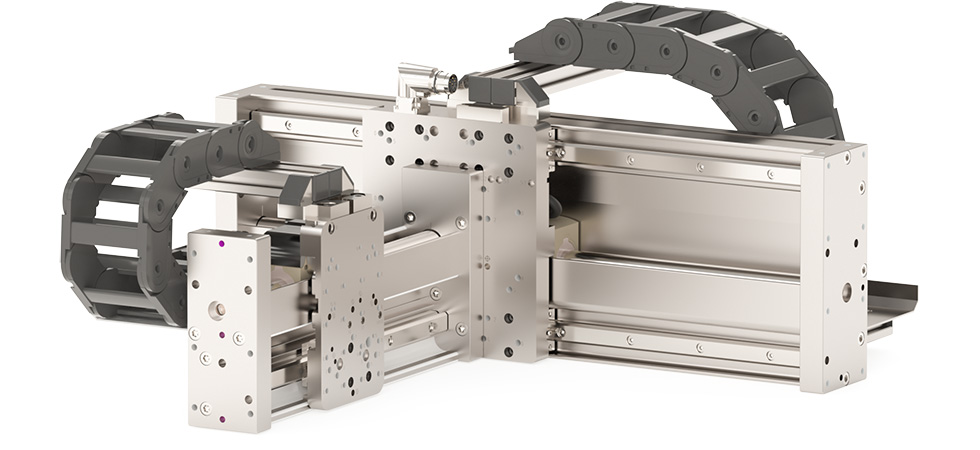

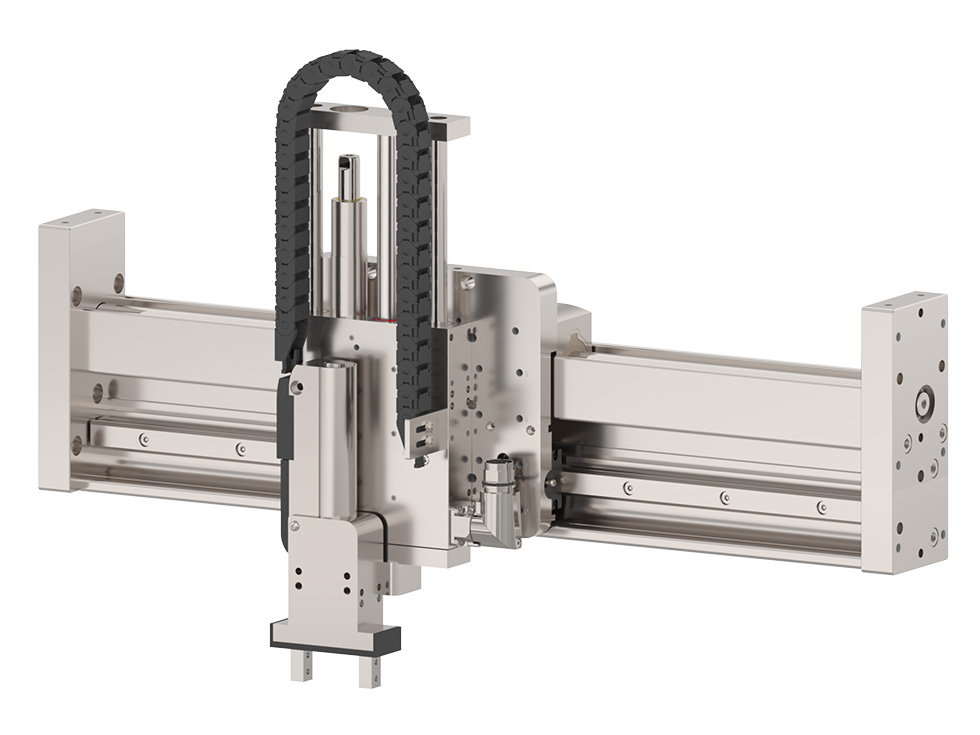

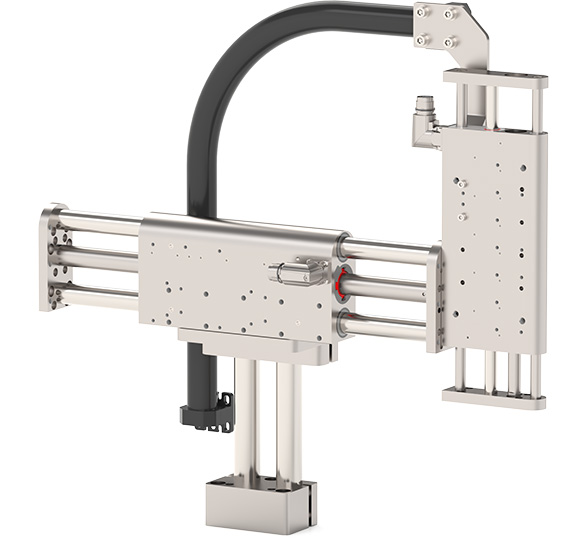

As Andreas Nowak, Managing Director of TEAM Automation Berlin, explains, in-house solutions are always possible but at the same time, one of the biggest challenges of conventional drive solutions arises: “In pick-and-place applications, the Z-axis must also be equipped with a motor. However, this significantly increases the moving mass on the X-axis, which in turn requires a larger motor for that axis.” Especially with typical stroke lengths of around 200 mm, such cantilever designs result in high moving masses, large space requirements, and insufficient rigidity – particularly in dynamic applications. LinMot’s Flat Robots and Systems directly address this fundamental issue: they are exceptionally spacesaving, modular in design, and purpose-built for the handling tasks that define modern automation.

Another key challenge in automation is flexibility. The continuously growing variety of component types that need to be assembled quickly pushes conventional solutions to their limits. “When I have three differently positioned feeders to bring components together, pneumatic systems soon reach their limits. LinMot axes, on the other hand, offer the required flexibility and the dynamics to match,” explains Mr. Nowak. Indeed, LinMot Flat Robots and systems offer decisive advantages through their unique motion structure: compared to other kinematics, they are not only more energy- and cost-efficient, but also far more flexible in workspace design. At the same time, they combine high speed with precise and repeatable motion control. This makes them ideal for applications that require exact movements and repeated positioning — from high-speed sorting and pick-and-place tasks to assembly, capping, screwing, and handling processes.

A further key advantage of LinMot Flat Robots and systems lies in their modular design. This allows the compact LinMot linear motors, modules, and guides to be flexibly combined into proven Cartesian structures such as semi-gantry, gantry, or other multi-axis systems. The result: solutions that enable even complex, industry-specific requirements to be implemented quickly and precisely — while maintaining high dynamics. Despite the integration of multiple carriages and Z-axes, the Flat Robots and systems remain extremely space-saving, low in interference contours, and easy to maintain and expand.

The reliable PR02 linear rotary motor is now available in a hygienic stainless steel version, ideal for use in the chemical, pharmaceutical and food industries. This makes the PR02 even more versatile, offering increased resistance to cleaning agents and minimal maintenance requirements.

“The LinMot axes provide the necessary flexibility and Dynamics.”

Andreas Nowak

Managing Director at TEAM Automation Berlin

For machine builders aiming to stay competitive, standardized drive components are almost indispensable. The reason is obvious: well-thought-out base solutions save not only costs but also valuable engineering time. With its Flat Robots and systems, LinMot offers a broad portfolio of basic configurations that combine dynamics and precision in a highly compact design. “After all, the product itself often defines the requirements. For our application, we needed very narrow handling units and the LinMot solutions were the perfect fit right from the start,” confirms Mr. Nowak. This is further enhanced by a wide range of options such as external encoders, force or torque sensors, hollow shafts with air feed-through, or preassembled trailing chain solutions — that add even more flexibility. The result is the perfect combination of standardization and individuality: specific requirements can be implemented without compromising fast and efficient realization.

To the Flat Robots and Systems

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information