Already uneatable before expiry of the best-before date? Pieces of plastic and metal in the pre-packed meal? Contaminated medicines resulting in damage to health? Automation components are counted among the 8 most critical sources of contamination in the processing industry and are often responsible for unwanted particle emissions. Since these components are often located in the immediate area of the product being processed, e.g. during capping, outfeeding and various pick-and-place processes, it is of crucial importance that the actuators used there, such as those from LinMot, also offer a high level of hygienic safety.

Download all informations (PDF)

The cause for the release of particles on classic actuator units lies primarily in the tribological stress, as a result of which wear occurs and thus particle emission. However, other types of contamination such as outgassing, germs and bacteria as well as electrostatic discharges and electromagnetic fields can also lead to considerable quality losses and reject rates in the manufacturing process, even in the smallest quantities.

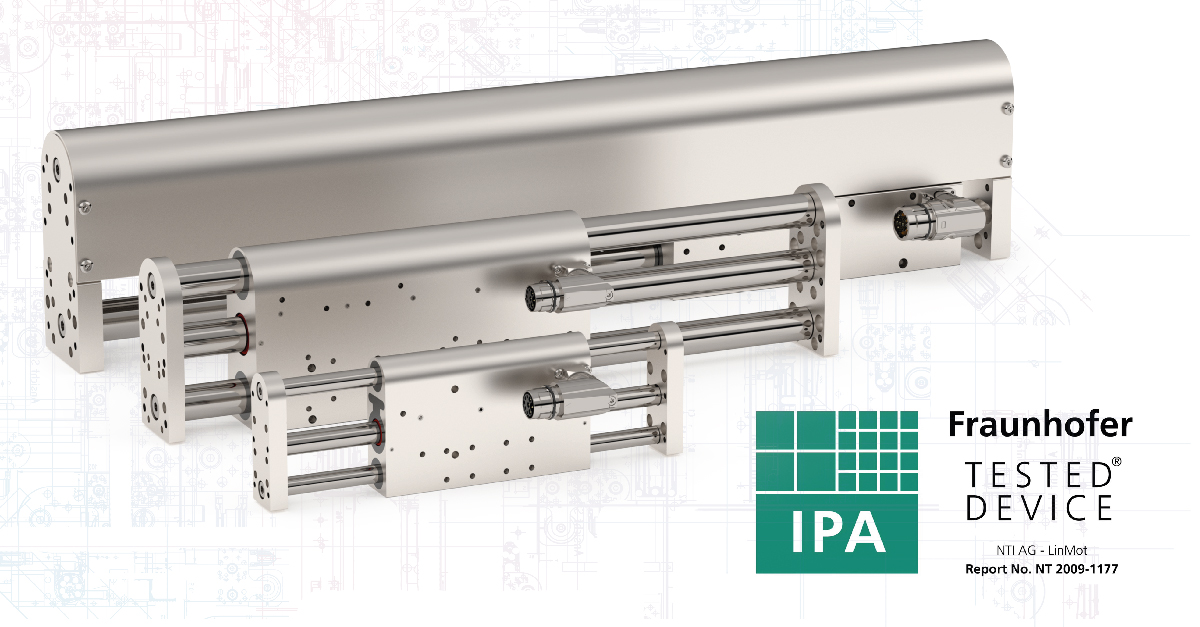

LinMot products score particularly well against the release of abrasive particles. The modules of the DM01 series do without mechanical transmission elements such as couplings, spindles or gears and transmit the force directly to the load to be moved. The guide elements are sealed to the outside and the linear motor is mounted in such a way that contact between the stator and slider is minimal, if it occurs at all. In this way, mechanical wear and thus particle emissions are reduced to a minimum. The easy-to-clean surface also counteracts other types of contamination and makes the modules ideal for use in demanding cleanroom environments.

More informations about our DM01 linear modules

As an independent and public research institution, the Fraunhofer Institute provides objective, scientifically founded statements on the contamination properties of LinMot components as well. The particle emission behaviour as the most relevant cleanliness property of the DM01 series was examined by the Fraunhofer IPA according to the standard 184-230609797 and the linear modules were certified with the test mark „Fraunhofer TESTED DEVICE®“ for cleanroom class ISO 4.

According to a study by the Fraunhofer Institute, the demand for cleanroomcompatible actuator units has increased in the following industries in particular:

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information