Prof. Dr. Kurt Spiegelmacher is a professor at Kaiserslautern University of Applied Sciences. His area of research is production automation with handling, transport and assembly systems and robots.

LinMot: SYSCONA, a well-known company in the beverage industry, has developed a new rejection system. Aren’t rejection systems for containers such as bottles or cans, or those for cartons or crates, already ‘exhausted’?

Prof. Spiegelmacher: Rejection systems completely exhausted? Not at all. Active rejection systems have been available for many years for containers that are particularly prone to falling or toppling over, such as empty returnable bottles, in which the containers to be rejected are gently pushed to the side in synchronisation with the transport speed. Thanks to the special design of the pushers, even very small distances between containers can be handled without any problems. However, the disadvantages are the relatively large space requirement and the heavy-duty mechanics with the associated maintenance requirements.

LinMot: So the need was for a compact, low maintenance rejection system?

Prof. Spiegelmacher: That is correct. Today, systems are known that use mostly pneumatic ‘fingers’ to form a railing at which the objects are deflected sideways. However, such deflectors are passive, i.e. the sideways movement is caused solely by the forward movement of the objects. In addition, braking friction forces act on the railing, which can also lead to falls at higher speeds. This can be countered by active guidance systems: For the first time, a segment deflector has been invented with a variable deflection angle, which is adjusted using LinMot’s linear drive technology. The unique, patent-pending ProfiCurve solution from SYSCONA, which automatically adapts to the transport speed, container characteristics and deflection tasks, overcomes the disadvantages of conventional segment deflectors and enables long-term savings in operating costs.

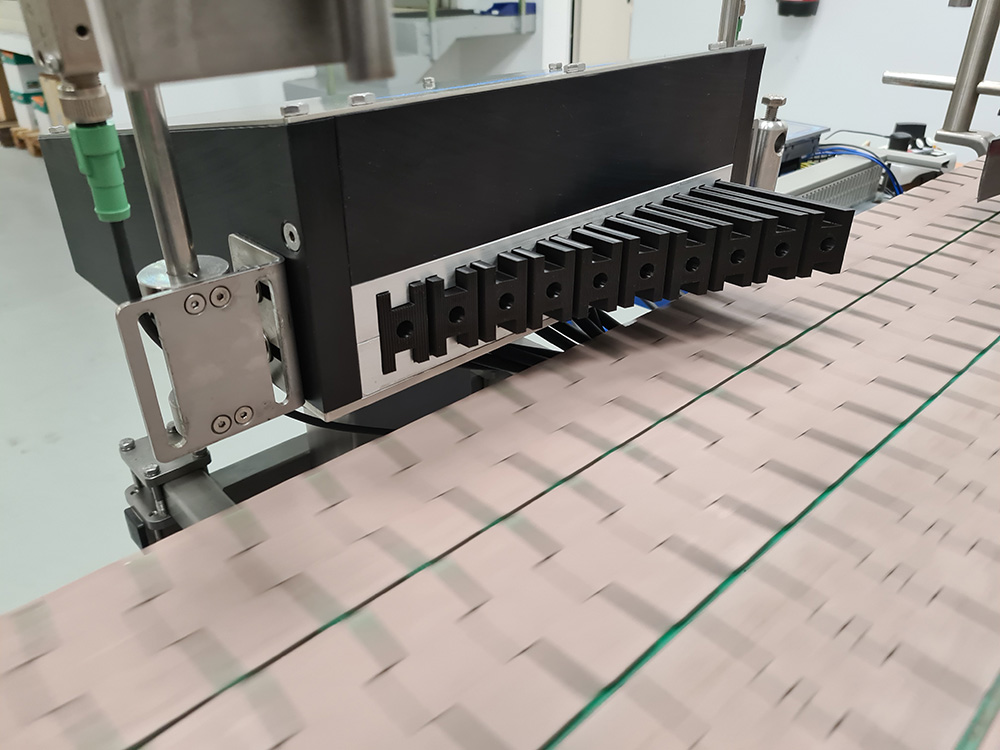

The capabilities of SYSCONA’s brand-new ProfiCurve deflector open up a whole new world of possibilities in the construction of conveyor systems. SYSCONA uses 25 mm wide high performance linear drives from LinMot’s P01 series with a stroke of 100 mm.

LinMot: So that’s how LinMot came into the game?

Prof. Spiegelmacher: Yes, SYSCONA is pleased to use the state-of-the-art linear motor technology from LinMot as the basis for the new ProfiCurve rejection system. Thanks to the free programmability of the stroke movement of each rejection element (linear motor with finger), the individual stroke movements can be triggered and parameterised depending on the belt speed. The speed data can influence both the stroke kinematics and the positioning angle of the finger cascade. The movement of the objects and the deflection width can therefore be set very precisely and kept constant from a control point of view.

For the first time, a combination of passive and active deflection has been achieved using the potential of LinMot linear motor technology in conjunction with a segmented deflection curve.

LinMotSo the ProfiCurve is not only compact and low maintenance, it is also intelligent?

Prof. Spiegelmacher: And much more. Thanks to the modular design, the number of active LinMot linear actuators can be adapted to suit the object, transport capacity and intralogistics function. The associated LinMot servo drives also offer a wide range of programming and control options, so that container guidance is extremely gentle. In addition to the small space requirement, the comparatively low and cost-saving energy consumption (electricity instead of compressed air) and the very low noise emission should be emphasised. Thanks in part to LinMot’s linear technology, the ProfiCurve rejection system can be easily integrated into fully networked production and packaging lines – an important contribution to Industry 4.0.

The collaboration between LinMot and Syscona is constantly creating new systems. Take a look at our application film.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information