Just think of the battery-powered lawn edger back in 1973 or the watering computer from the 1980s, GARDENA has always proven to be a particularly sustainable innovator. However, the age of Industry 4.0 and the increasingly clear ecological and economic limits of resilience also present the globally active subsidiary of the Swedish Husqvarna Group with the challenge of producing in a more networked, faster and, above all, more environmentally friendly way. Fundamental prerequisites for future-oriented and sustainable production have already been met thanks to a partner: With state-of-the-art linear rotary and linear technology from drive specialist LinMot, GARDENA has succeeded in redefining the precision, speed and sustainability of its production facilities.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

GARDENA gave us a fascinating insight into the production of its biggest seller. Find out from our video how the Swedish Husqvarna subsidiary has managed to redefine precision, speed and sustainability of its production facilities with our technology.

Back to the roots

130 litres per capita. This is how much water every person in Germany uses every day for drinking, washing, cleaning and cooking. A considerable amount, but only a fraction of the actual total consumption. This is because an often invisible indicator, so-called virtual water, contributes much more to the overuse of water resources. If this embedded water, which is needed for the production of food, beverages, clothing and other consumer goods, is included, the water footprint amounts to around 7,200 litres per day per capita, or 219 billion cubic metres per year for the whole of Germany – according to the results of the research project at the Technical University of Berlin. There is no doubt that industrial manufacturers in many sectors with their production facilities, some of which are the size of halls, have a significant share in the exploding figures for consumption-induced water consumption. However, GARDENA is aware of this responsibility and the associated consequences and has been designing its production processes for decades with an ecological view of the future of water. “Both our products and their production should be more gentle, more efficient and more economical,” is how Heribert Wettels, Communications Manager of Public Relations at GARDENA, briefly summarises the company philosophy.

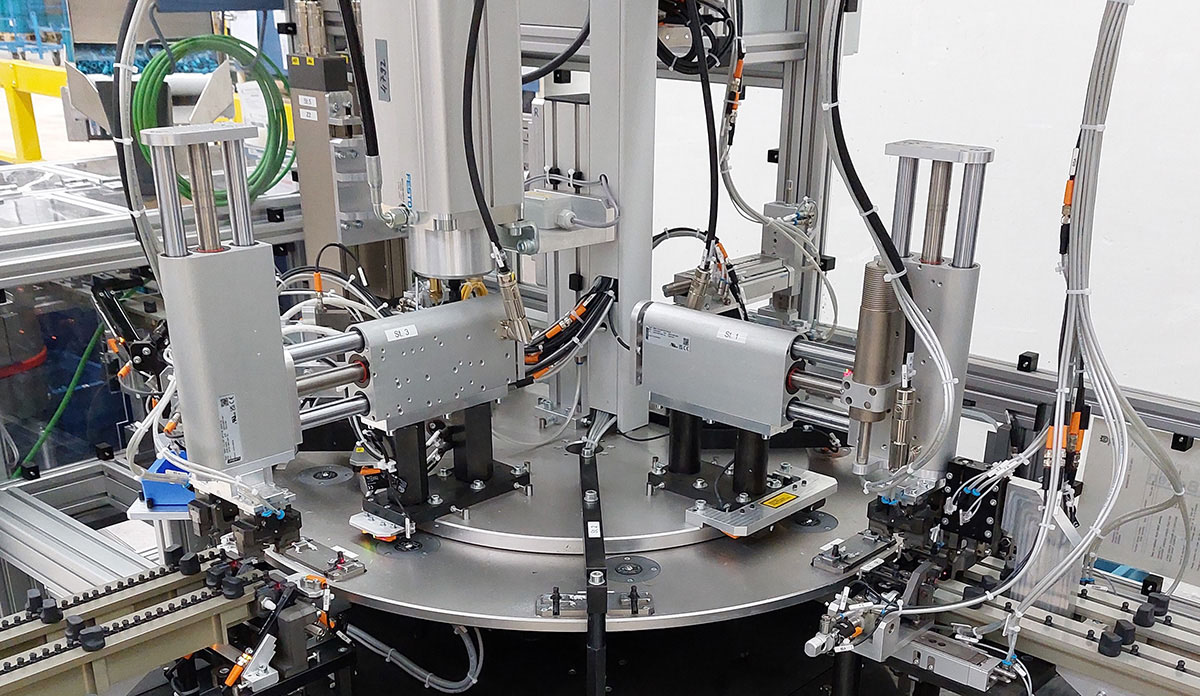

The fact that this philosophy has always been lived practice is best demonstrated by the Husqvarna subsidiary’s modular drip irrigation system, which has been the absolute market leader in the consumer sector for decades. The Micro-Drip System (MDS) is a resource-efficient irrigation solution that delivers water drop by drop to where plants need it: the roots. “The very first version of the MDS was launched in 1985. That was long before the big sustainability debates and droughts in Europe,” says Heribert Wettels, Head of Communications, explaining the history of the irrigation system’s origins, underlining the company’s environmentally conscious approach, which has also had an impact on the automation technology of the production facilities over the years. “Since the new generation of the Micro-Drip system was renewed from the ground up, it was also necessary to further develop the production system behind it and its drive technology,” says Reinhold Steck, design manager for special machine construction at GARDENA, explaining the technical aspects of the change. As the MDS system is already in its fourth expansion stage, this advancement in the manufacturing processes also had to take place at almost all levels of the drive technology. “In the first three expansion stages of the MDS, conventional solutions were in use,” says design manager Steck. Since the new system generation was to offer more basic and process reliability, increased precision in force control and process parameters as well as optimised sustainability and energy efficiency, the path for the special machine construction department inevitably led to a manufacturer, according to Steck, “where we finally found the solution for our demanding pick-and-place tasks. Because it is precisely in these processes that the LinMot drive systems are unbeatable in terms of their dynamics and precision.”

PR02 – Precision at the push of a button

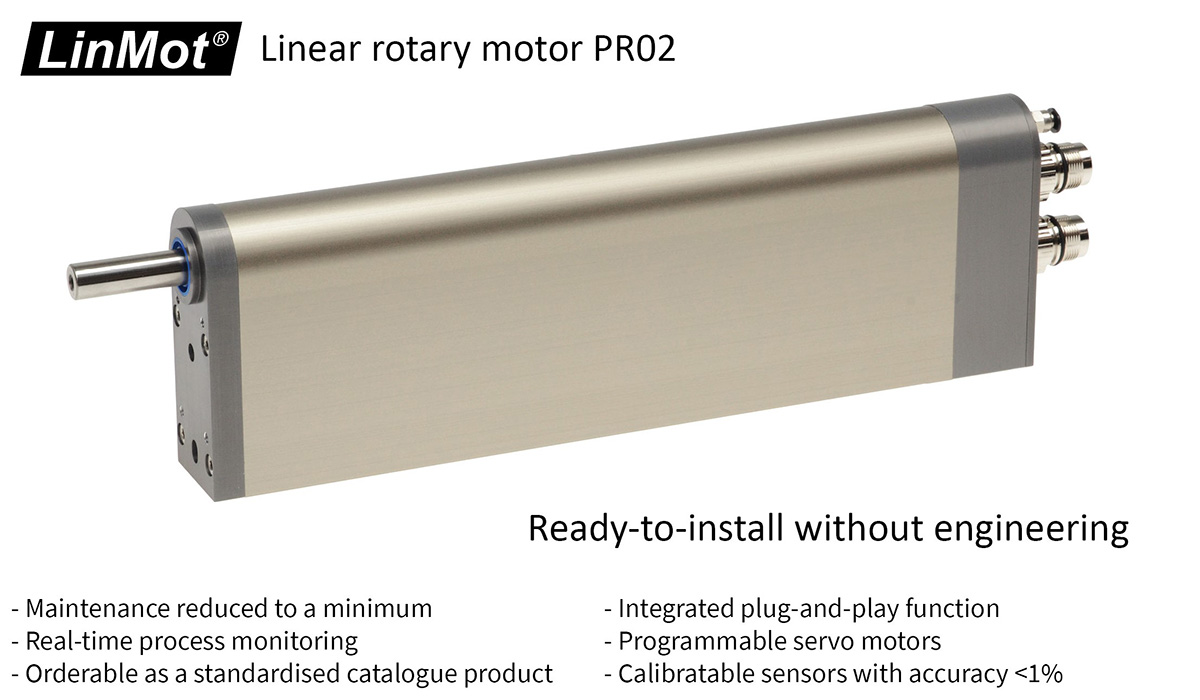

Implementing industrial systems for precise and dynamic closing, screwing or assembly is an extremely complex challenge with conventional servo solutions. The various components, such as the two types of servo motors, grippers, hoses, sensors, etc., must be coordinated with each other and included in the engineering. This makes the realisation of efficient industrial machines planning-, material-, cost- and time-intensive and yet does not promise the full precision and versatility in the processing – as is the case, for example, with the Micro-Drip-System from GARDENA – of small dimensioned components. For example, the row dripper for row crops and the end dripper, which is ideal for watering selectively and saving water even with height differences, are very small and therefore require a new level of assembly precision. “With two servo motors, it is possible to drive in a force-controlled manner, but with the large mass that has to be moved, the precision required with MDS systems is lost,” says design manager Steck, explaining the basic problem of small-part assembly with classic servo drives. This is where the first decisive unique selling point of the PR02 motors becomes apparent: thanks to the decoupled rotary servo motor of the LinMot linear rotary modules, only the motor shaft needs to be accelerated or braked, which means that the mass that needs to be moved is much smaller, both rotationally and linearly, and the feed force can be very finely defined, even in vertically aligned processes.

To the PR02 linear rotary motors

But it is not only the processes in the GARDENA plants that benefit from the properties of the PR02 motors. LinMot, as market leader in the field of tubular servo motors recognises all customer needs: Whether for screwing, assembling or capping, the linear rotary motors of the PR02 series are also characterised by their high flexibility, dynamics as well as safety and networking. Exactly reproducible and recordable motion sequences are ensured by calibratable force and torque sensors which, in addition to the setpoints provided from the servo controller, offer the possibility of monitoring and evaluating process parameters such as press force, torque, angle or linear position available in real time for each process with an accuracy of better than or equal to 1 % of the nominal value. “This also allows the control parameters to be matched much more precisely to the respective component contour,” confirms Mr Steck, pointing out the resulting benefits for GARDENA: “Thanks to the precision of the LinMot PR02 motors, our systems are more process-stable and the reaction and cycle times have become significantly shorter,” says the design manager. Whereas 15 years ago a cycle time of 6 to 7 seconds was completely sufficient for the production conditions and quantities at that time, the MDS systems and the LinMot lifting-rotating motors used in them are now designed as high-speed machines and operate with an output time of 1 to 2 seconds, and even in two lanes. “These cycle times are no longer feasible pneumatically,” says design manager Steck, pointing to the row dropper mentioned earlier. Thanks to the LinMot PR02, this can be screwed to the T-piece in just 0.3 seconds.

In addition, the LinMot components can meet other special requirements that result from the special position of the GARDENA design department: “A high degree of flexibility of the drives is particularly important for us, as we are always developing new, customised special systems for the respective new products,” reports the design manager. In the process, parameters and contours can change fundamentally and quickly on both the product and the machine side, so that readjustment of the individual positions must be quick, easy and precise. “Thanks to their flexibility, the LinMot components keep up with all adjustments to the production machines at lightning speed and all changes can be made in no time at all,” says Reinhold Steck.

Fully automated processes thanks to LinMot components: Regardless of the size, material, contour or complexity of the parts to be processed, complete pick-and-place processes are implemented quickly, cost-effectively and sustainably with LinMot linear modules and linear rotary motors.

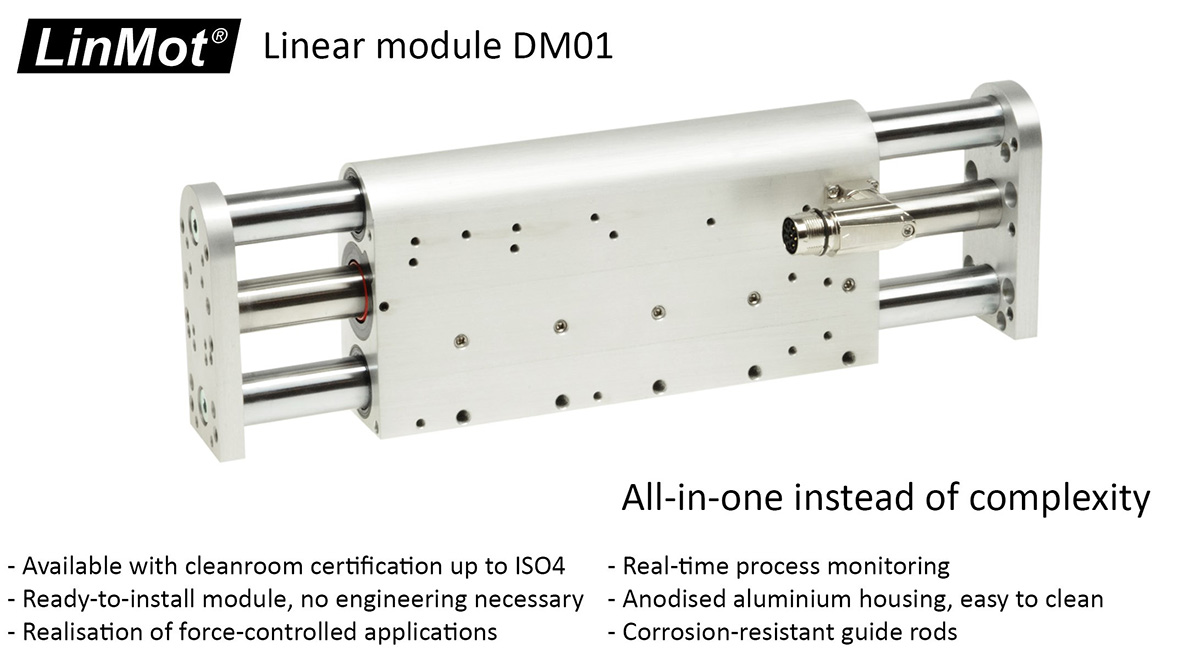

LinMot linear modules – complete package instead of complexity

The highly dynamic LinMot modules DM01, SM01 as well as SM02 are pre-assembled units ready for installation. They represent a further development of LinMot’s B and H guideways, which have already been in use for more than 20 years, and have all the design advantages of a modern drive. Heribert Wettels: “A GARDENA system is not an off-the-shelf solution. This also means that the components that are installed in it must have a high degree of flexibility. In addition, as special machine builders, our colleagues have to deal with many different technologies. That’s where the LinMots have to fit in perfectly.” A challenge that the LinMot linear modules master with flying colours: Because the DM01 modules are able to implement an infinite number of motion sequences for every customer application. With numerous strength classes, sizes and stroke lengths as well as optional, industry-specific accessories such as a completely washable motor interior for clean-in-place and sterilisation-in-place processes, stainless steel versions, fully encapsulated stator and stroke lengths of up to 2 metres, LinMot linear guides and modules are unbeatable in any production environment and machine.

The modularity of the LinMot linear modules also convinced the GARDENA engineers. On the one hand, the linear modules have the same control as the linear rotary motors already in use, which makes the electrical setup of the GARDENA systems much faster and more efficient. On the other hand, the numerous centring holes in the front plates and in the guide block enable fast, versatile and precise mechanical fixing of the load or other LinMot modules. “During the development phase, LinMot provided us with very intensive support,” says Felix Kaifel, head of software project planning for the MDS systems. This already allowed GARDENA to investigate the various processes and determine optimal programme sequences through a test setup. And so, thanks to the kinematics function of both assembled LinMot linear modules, both the X and Y axes of the motion sequence could be realised with ground corner points. “These advantages of the LinMot linear modules enable us to move much more gently on the drive and machine and at the same time faster without jerky movements,” reports project manager Kaifel.

Safe and effective with Safety Drives

It is well known that high safety standards apply in industrial production in Germany. For the

engineers at GARDENA, the Functional Safety offered by LinMot is therefore of particular importance. The LinMot Drives with the -2S option contain an integrated, certified safety module in the same housing. In conjunction with -2S motors, this enables the implementation of safety functions such as safely reduced speed (SLS) and safely reduced stop (SOS). “With the -2S Safety Option from LinMot, we have not only become safer, but also more comfortable, both in troubleshooting and in commissioning the production systems,” explains project manager Kaifel. For example, thanks to the high basic safety of the LinMot -2S components, the safety gates of the systems can be opened when the motor is energised in order to teach positions or to rectify faults. “Such fault clearance is not only safer, faster and more efficient, but also increases system availability. This has proven to be an essential advantage for a quick start of production and sales for all our seasonal garden products from GARDENA,” says the head of software project planning.

The absolute all-rounder for pick-and-place applications: The outstanding modularity and combinability to two-axis systems as well as accelerations up to 50 m/s and speeds up to 5 m/s make conventional solutions look old-fashioned and make the LinMot DM01 modules unrivalled in every customer application.

Sustainability or efficiency?

About 15 years ago, this was indeed a decision question where sustainability ruled out efficiency or efficiency ruled out sustainability. Today, however, the cooperation between GARDENA and LinMot shows that climate-friendly industrial production and increased efficiency do not have to be mutually exclusive, but can even lead to further benefits with the right drive technology. For the partnership between GARDENA and LinMot makes a double contribution: on the one hand, products are created that deal with natural resources in a way that is footprint-friendly, and on the other hand, new manufacturing processes are developed that help to efficiently reduce the consumption-induced water consumption of industrial production. “For GARDENA it is only logical to invest in sustainable automation technologies. The partnership with LinMot will therefore develop strongly,” Heribert Wettels, summar ises. “The systems are already being delivered to the plants in the Czech Republic, China, USA and Australia. This means that the special machines with LinMot components are just as globally positioned and popular as the GARDENA company itself.”

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information