Safe drive system in standard format – Until now, machine builders were largely left to their own devices when it came to ensuring functional safety when using dynamic linear motors. Now, for the first time, a complete package is available that makes this step much easier for users: Linear motor manufacturer LinMot has integrated safety features and some new additional functions directly into the motor and controller, taking care to ensure that they are identical in design to existing products. This means that both new and existing machine concepts can benefit equally from the numerous advantages of integrated safety technology.

In particular, producers of handling and assembly technology, packaging machines, and solutions for laboratory automation, but also many other products, value linear motors for their flexibility and dynamics. At the same time, however, the high accelerations and forces that occur during operation of the motors also represent a potential hazard for the operating personnel and the machines themselves. Affected drives must therefore be effectively shielded or monitored by safety technology and brought into a safe state in the event of an emergency to minimize risks during operation and meet the requirements of the current Machinery Directive.

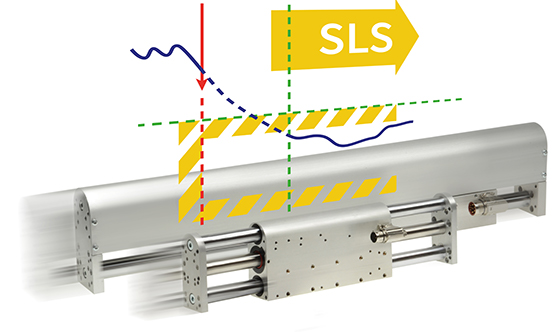

However, the high traversing and acceleration values achievable by linear motors present conventional safety technology with virtually unsolvable challenges in practice. One of the most common and basic safety functions is disconnecting the motor from the power supply circuits (Safe Torque Off, STO). Depending on the power to be switched and the relay used, the switch-off time required for this varies. For motors used in general mechanical engineering, it is certainly in the range of 20 to 50 ms. This is normally sufficient for rotary motors and the most basic STO functions, where opening the safety door is the triggering element. However, with the more dynamic linear motors these long switch-off times pose a problem with regard to safety. Most functional safety systems, such as with Safe Limited Speed, the motors are also energized in the safe state and they can develop high travel speeds within a very short time. Significantly shorter reaction times are therefore required to achieve the required safety level. This requires the integration of the necessary safety function directly into the controller. LinMot has therefore developed a corresponding integrated safety solution for its linear motors with the shortest possible reaction times and was certified by TÜV Nord.

New C1251 series of drives with integrated functional safety functions.

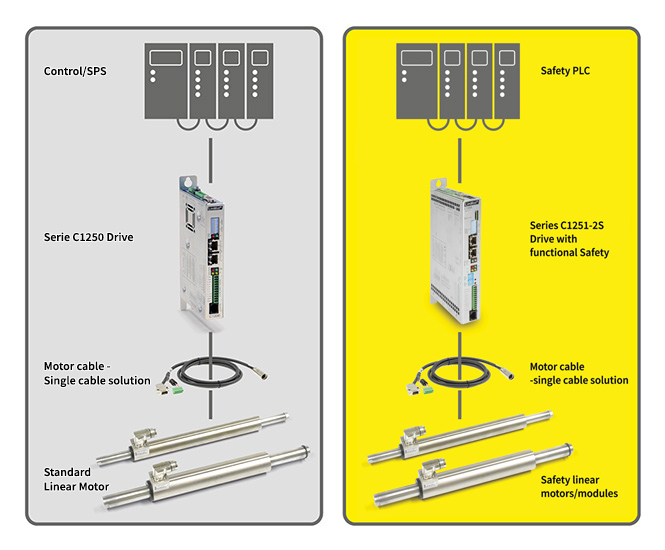

At the end of 2021, the manufacturer of industrial linear motor systems will start the market launch of this new servo drive series C1251 with integrated safety technology. At the same time, the company will offer the familiar P01 series linear motors with a safe encoder system. Together, they form a consistent, certified overall package.

This means that for the first time, users of linear motors have a safe drive system at their disposal, which has been the case in the field of rotary motors for a long time. Times where they had to combine products from different manufacturers and ensure functional safety in all aspects themselves are thus a thing of the past. The associated reduction in certification effort for the user should not be underestimated. After all, not every combination of a safe drive and a safe controller is safe by definition when working together, and the corresponding verification is difficult and labor-intensive. With LinMot, on the other hand, the system consisting of a safe controller and a safe motor (incl. encoder) is certified by default.

In realizing the new product families, LinMot has drawn on motor and controller hardware that has proven itself over many years in order to provide users with the best possible technology and to facilitate integration into new and existing machine concepts. The C1251 drive series, for example, is based on the drive technology underlying the C1250 servo drive series. In order to make a generation change as simple as possible, the non-safety-relevant software parts of the existing controllers were adopted for the new C1251 Drive family. The new safety functions can be added with the correspondingly expanded LinMot-Talk configuration software. They are thus integrated directly in the controller and do not require any additional hardware, which offers shorter commissioning times and greater cost-effectiveness through efficient engineering and less wiring effort.

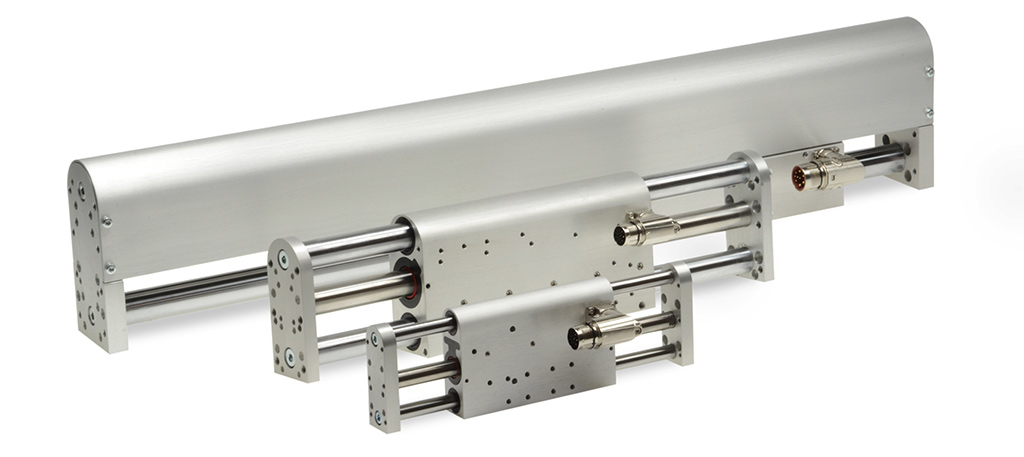

The compact design and permissible operating conditions could also be retained for the linear motors despite the additional safe encoder system required, since LinMot has made the proven LinMot encoder system fit for the safety application especially for these motors together with TÜV-Nord. This allows machine builders to offer machines of the same design with and without safety functions side by side in a particularly cost-effective manner with minimal additional effort.

Safe and “gray” drive solutions do not differ at LinMot in terms of design or space requirements.

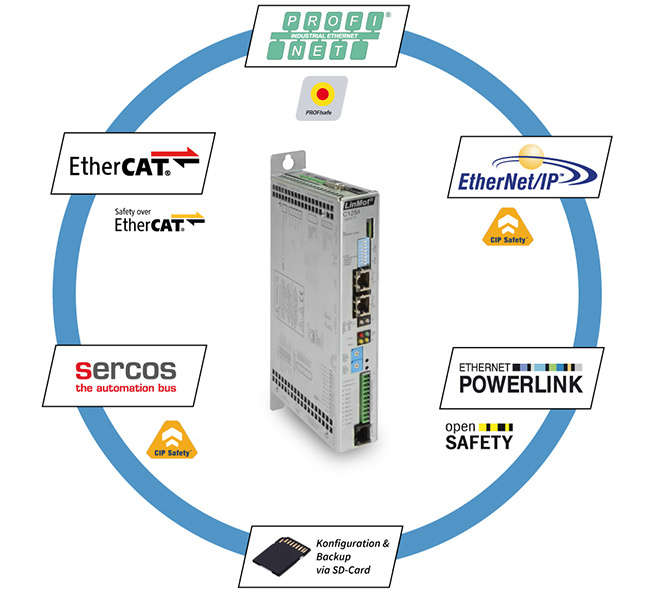

In the further development of the drives, the linear system manufacturer has also made sure that the handling of the drives is once again significantly simplified. It is now possible to define the interface used for communication with the machine controller via software. This means that machine builders no longer have to keep different drives or communication modules in stock for different customer groups. Requirement specifications that call for the use of different communication protocols or machine controllers can be implemented with just a single item. One drive covers all common buses such as PROFINET, EtherCAT, Ethernet IP, SERCOS or POWERLINK as standard.

The safety-related integration of the drive-motor combination takes place via safe bus connections. LinMot made a start with PROFIsafe. Other safe profiles such as Safety over EtherCAT and CIP-Safety are in the works or are already in the certification process. Alternatively, up to two of the integrated safety functions can be called up by the safety controller via safe, digital I/Os.

In addition to these additional safe I/O’s, LinMot engineers have equipped the C1251 series drives with a flash card slot. The drive configuration, including the configuration for the safety functions, is stored on the appropriate SD card, which can be loaded from the drive when the card is inserted. This makes it easy to replace the drive hardware if necessary without losing any data, or to load new drives with the desired software: Simply insert the flash card with the desired data set into the controller. The data can be read in at the next startup. The connection of a computer or the LinMot-Talk software is not required for this process, which simplifies and speeds up maintenance and production processes. Validation of the safety configuration can also be carried out by manually entering the checksum via special rotary switches directly on the drive without a PC on site.

Software-selectable communication profiles and an SD card for data backup reduce storage, logistics, spare parts and service costs.

LinMot has been using a single-cable solution for connecting the drive and motor since 1997. The company also follows this proven concept with its safety solution. Thus, the power and signal cable already used in the previous generations is part of the safety package and special cables can be dispensed with. The user of LinMot motors therefore does not have to deal with a separate cable for the encoder signal and one for the power, including the necessary connectors, even with safe drives. The incurred costs and the effort required for engineering, assembly, warehousing and maintenance are correspondingly lower. Additional positive aspects are reduced space requirements, fewer sources of error and thus higher system availability.

LinMot has optimally expanded its comprehensive product range for linear and rotary movements with the integrated safety solution. Users benefit from a complete package for the implementation of linear movements that significantly accelerates the setup and certification of safe drive systems. Other benefits include short response times, less wear and tear due to the elimination of mechanical components, as well as a smaller implementation footprint and, last but not least, greater machine reliability. The integration of safety functions thus has a direct impact on the total cost of ownership of a machine. In the first step, LinMot has implemented this concept in its standard linear motors. The remaining drives from the extensive product range, such as linear rotary motors or linear modules, will follow step by step starting in 2022.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information