Rotary indexing machine combines advantages of piston and flow-rate metering: Many users wish they could combine the advantages of flow-rate metering and piston metering in one rotary filling machine. Tölke, a specialist in packaging machinery, has pulled off this feat by using LinMot linear motors. The operator of the system benefits from short changeover times, less scrap, shorter downtime, and a more flexible machine.

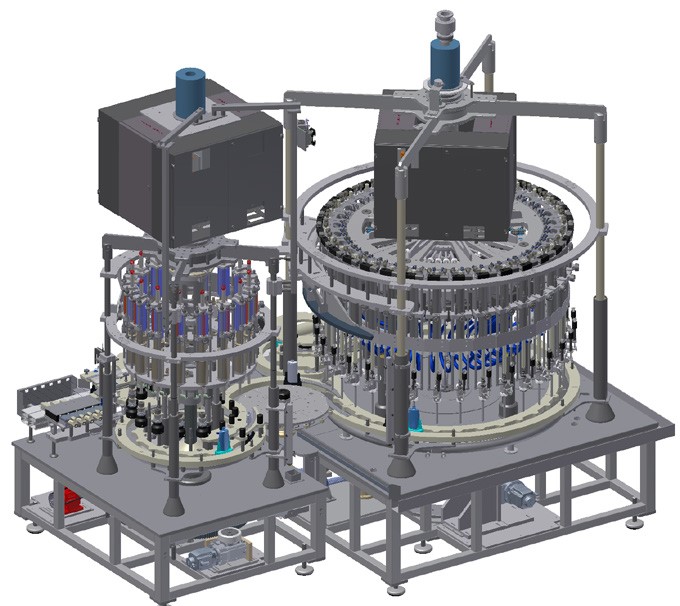

Flexible filling and closing machine from Tölke for handling up to 300 bottles/min at a fill volume of up to 250 ml. (Rendering: Tölke)

«Mechanical cam discs have proven their worth for implementing linear-motion processes for decades and will continue to be used in many lowerand medium-performance filling and closing machines in the future,» says Franz-Josef Patzelt, one of the managing directors of Franz Tölke GmbH. «With their electronic pendants, however, the filling process is much easier to adapt to individual product requirements, and product changeover can be done much more quickly, which more and more users are demanding.»

Competing metering methods

Previously, metering in simpler rotary filling machines was typically provided by pistons, where the stroke of the piston was controlled by a mechanical cam disc. The advantage of piston filling is that the volume that has already been dispensed during the filling process is always known. This is applied for media that tend to foam up, for example, by using the cam disc to raise the filling needle synchronously as the fill level rises, so that it does not dip below the surface of the medium. Despite this appealing advantage, there are also some disadvantages to the piston approach. The piston is hard to clean, simply because of the seal it requires, and is not very well suited to CIP/SIP. The mechanical force applied by the piston also causes changes in some products. Another disadvantage is that large fill volumes require large pistons, which means that a change in the amount dispensed is difficult to implement without a time-consuming changeover of the machine.

As an alternative to piston metering, therefore, the fill level can be determined by measuring the flow rate of the pumped volume. The advantage of this method is that the fill level can be modified easily when the product is changed. The mechanical forces on the medium are also minimal, and there are no mechanical parts that require maintenance. CIP/SIP cleaning is not a problem.

Decoupling the motion sequences

«With a carousel with fill-level metering based on the flow rate, the filling speed is decoupled from the cam-controlled motion of the filling needle,» considers Franz-Josef Patzelt. This means that when the machine is running slower or faster than its nominal speed, the containers will be filled sooner, or not until later. «Depending on the speed, the machine would then need 270° or just 30° of the rotation of the dial table,» says the Tölke director, explaining the problem. «This means that the filling needles can dip into the product during the filling process, or the drop height above the surface is too great and there is a risk that the machine will be contaminated with dripping product residue or air bubbles will get into the product.» In the past, this has forced bottlers to return to linear machines when working with products that tend to foam up. In these systems, the filling needles can be mechanically coupled and raised synchronously with the fill level relatively simply, using an electric motor. Due to their construction, however, linear filling machines can handle only small to medium filling rates of several thousand bottles an hour. For hourly filling rates of over 10,000 bottles, only rotary machines can be used. Here, however, every needle must be raised individually at the right time in order to avoid submersion at different machine speeds and to keep the drop height to a minimum. There is no alternative but to precisely control the position of the axes. Tölke has now managed to do just that with high-performance linear motors from LinMot.

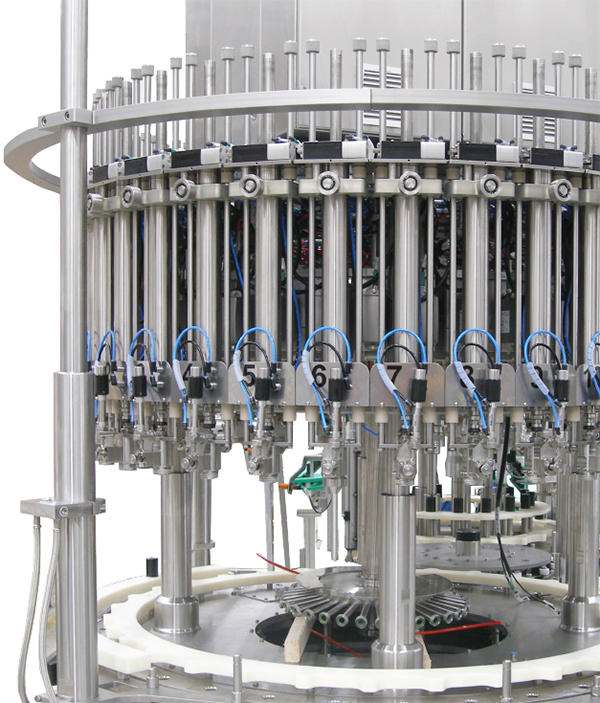

The monoblock system has space for 36 filling stations, in which each filling needle is driven by a LinMot linear motor. This allows rapid product changeover and broadens the range of application of the filling and closing machine. (Photo: Rossmann)

Flexible carousel with linear motors

The users of a carousel machine with electrically driven filling needles enjoy a whole series of additional advantages. Product changes require nothing more than an adjustment of the stroke of the filling needle and can be managed with the push of a button. This eliminates the need for time-consuming and costly reconfiguration of mechanical cams. A wide range of travel profiles can also be implemented, so that differently shaped bottles can be filled without changing the entire structure of the machine. The precise position-measurement system of the linear motors also allows the motion of the filling needle to be controlled with an accuracy in the range of tenths of a millimeter above the product surface. The acceleration levels for lowering and raising the filling needles can also be adjusted to meet individual needs, in order to reduce the loads on the mechanical systems and optimize the handling of the filling medium. «Even highly dynamic raising of the needles is possible with linear motors, unlike with mechanical cams, as there are no damaging forces acting on the bearing shafts,» explains Markus Kröger, the responsible project manager at Tölke.

Resume production quickly after a defect

Tölke has made use of the fact that LinMot motors mechanically decouple the filling-needle stroke from the motion of the carousel or dial table in order to consistently advance the modularity of the machine.

Every filling module is now an autonomous unit consisting of a flow meter, linear motor, servo controller, and filling valve. If a filling station is damaged, it can now be replaced in a short time, so the machine can get back to work much faster after a crash, for example. Decoupling has also made it possible to finish the filling process for all of the containers on the machine prior to a planned machine stop and to place the machine in a safe state. The technology also makes it possible to design the machine controls so that if a single filling station fails, the affected filling heads move to a safe position and are removed from the active filling process. This reduces machine downtime to a minimum.

Ready for Industry 4.0

The use of linear motors has even more advantages that optimally support the modern concept of «Industry 4.0». Information provided by the servo controller, such as the current motor temperature or the acceleration curve, can be used to monitor the filling process and detect problems with the mechanical systems (condition monitoring) or collisions at an early stage. The machines that Tölke has equipped with this new technology include a blocked filling and closing machine with 36 filling stations and 16 closing stations, where the strokes of the filling needles are each perfumed by linear motors from LinMot (series PS01-48 stators with series PL01-27 sliders).

The series P01-48 linear motors, completely encapsulated in stainless steel, are deliberately designed to be compact and do not require gaskets, unnecessary edges, corners, holes or threads. (Photo: LinMot)

Stainless steel motors with IP69K

These direct drives are made entirely of stainless steel (1.4404/316L) and are notable for their high protection class, IP69K. Gaskets were deliberately eliminated from the motor design. All connections are welded. The motors are also fully potted in order to prevent condensation from forming. Thanks to these features and the closed, easy-to-clean stainless steel surface, the INOX motors are an excellent match for use in machinery and equipment that processes food products, cosmetics, or pharmaceutical goods. This was not the only reason, however, that Tölke decided to use these stainless steel motors from the Swiss company. The low space requirements of LinMot motors was another deciding factor, as the available space on the rotary table is tight. «The LinMot linear motor, as an integrated unit, is much easier for our designers and assemblers to use than a servomotor-ballscrew combination, and it takes up less space,» summarizes Markus Kröger. «This makes it the ideal solution for systems where the filling process needs to be as flexible and efficient as possible, like our high-performance carousels.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information