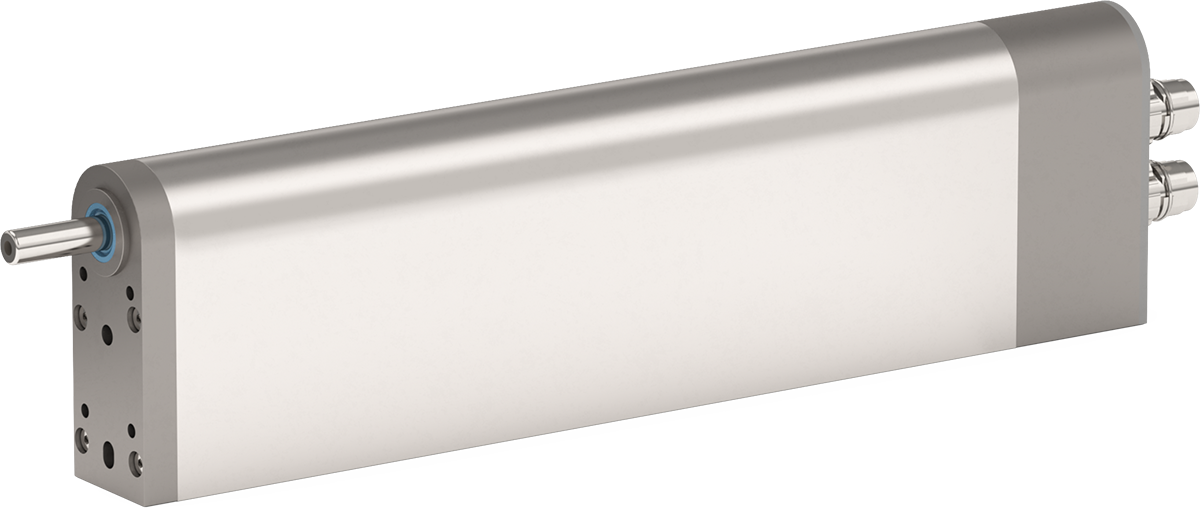

With LinMot®, slim design and full functionality are no longer contradictions. The latest example of this is the PR02-40 stroke rotary motor. With an overall width of just 40 mm, it is the most compact drive in the PR02 series, yet offers all the optional features of its larger counterparts.

Linear Rotary Motor PR02-40

The LinMot linear rotary motor is an actuator that combines both linear and rotary direct drive mechanisms within a single compact housing. These are individually and independently controlled by two drive controllers. Highly dynamic and freely programmable linear-rotary motion sequences can be achieved through the higher-level controller. These sequences can be executed either synchronously or independently of each other.

A wide variety of features, such as a magnetic spring, an integrated torque measuring shaft or a force sensor, can be integrated as options. This gives the customer the full range of functions. The MagSpring® passively compensates for the weight of the moving load and can also move the axis to a parking position when de-energised and hold it in this position. The torque and force sensors also enable precise, reproducible and recordable sealing and assembly processes.

LinMot offers a further option for demanding applications and to increase flexibility. A hollow shaft makes it possible to easily implement pneumatic grippers via compressed air or vacuum feedthroughs for suctioning a product.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

How our Linear Rotary Motors are working

The compactness and hygienic design of the PR02-40 actuators open up an enormous range of applications. For example, complex movements such as screwing, closing, transferring, stacking and aligning can be achieved with a single component.

The innovative PR02-40 provides all the necessary data packages for networked production in line with ‘Industry 4.0’. With the help of the drive parameters and the additional sensors that can be integrated, detailed information such as position, pressing force or rebound force, angle of rotation and torque is available. In many cases, this information simplifies time-consuming downstream tests or inspections, or makes them completely unnecessary. The user has full control over the process quality and can detect deviations at an early stage.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information