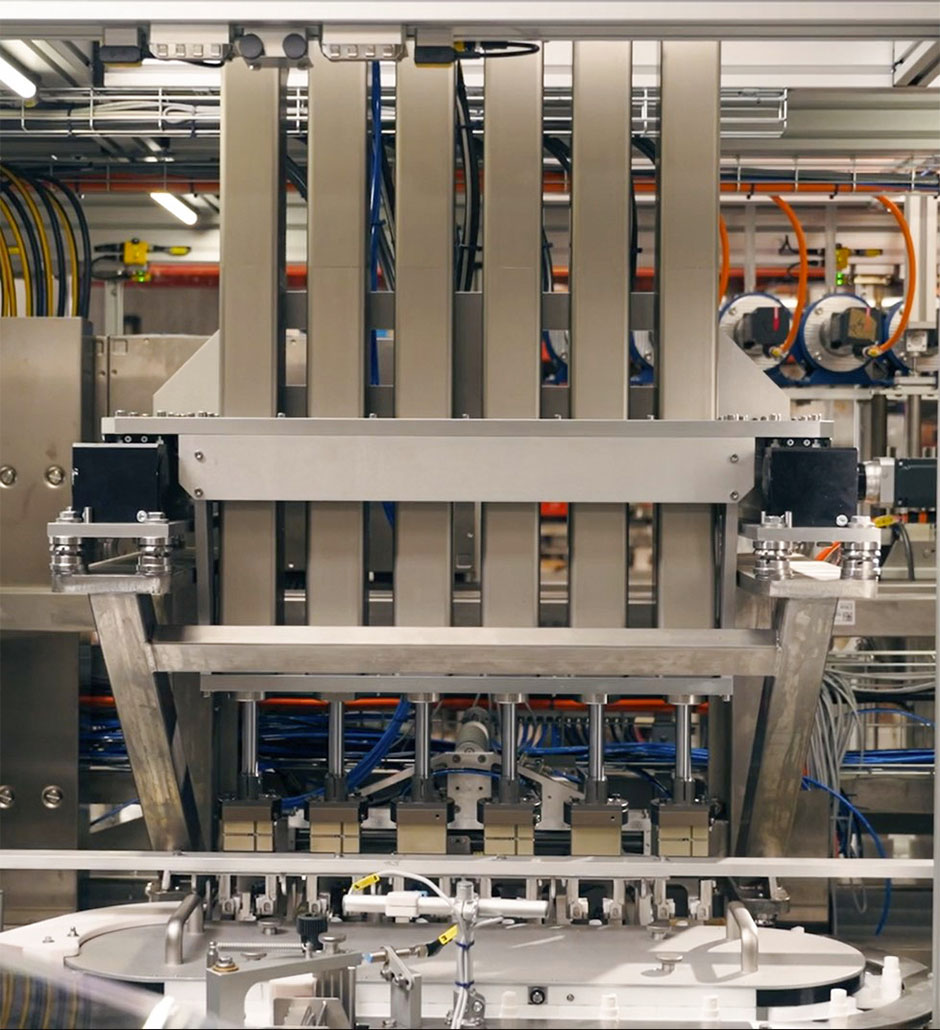

Selecting the right drives for a complete filling line is one of the most complex tasks in automation. Each individual station in the production process, from conveying and dosing to capping and packaging, places specific demands on the drive systems. In the case of special products, these not only have to be powerful and precise, but also meet strict requirements in terms of hygiene, corrosion resistance and particle emission. A challenge that LinMot was made for.

The challenge is particularly great when there are aggressive or sensitive substances to be filled, such as chemicals, food or pharmaceutical and cosmetic products. Drives made from conventional materials often do not offer the necessary resistance to chemical reactions, moisture or high temperatures that can occur in filling systems. Therefore, stainless steel products are often indispensable in lines with special substances and production conditions. LinMot’s stainless steel product line meets these requirements and provides drives that function smoothly in both hygienic and highly corrosive environments. Mr Eberhard Vaas, Managing Director of APA-Tec GmbH, is particularly impressed with the stainless steel linear guides in the LinMot range: “Any manufacturer can supply the drive, both rotary and linear, but the machine builder still has to design and build the guide himself. LinMot’s linear guides make this job much easier and save a lot of time,” says the managing director.

«We visit the LinMot stand at every exhibition to see the latest developments in automation.»

The LinMot SM01 and SM02 guides are manufactured from 316L stainless steel, which is recognized as the standard in the food, pharmaceutical and chemical industries. This is particularly important in filling systems where strict hygiene standards are essential.

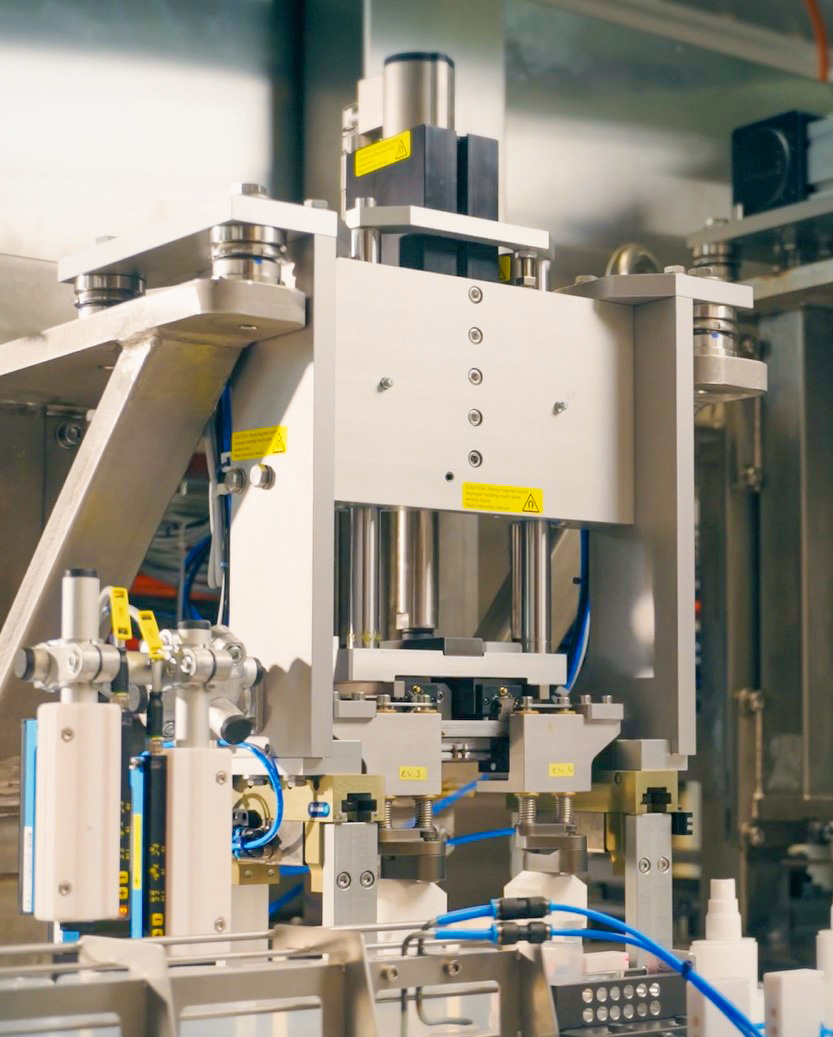

Creating industrial systems for precise and dynamic closing and screwing is an extremely complex challenge. The various components of such an application, such as different servomotors, grippers, hoses and sensors, must be precisely coordinated and integrated into the engineering. This makes the implementation, planning, material, cost and time intensive. The requirements for dynamics, repeatability, robustness and efficiency are high, and conventional drive systems often reach their limits when it comes to implementing effective closing processes. In addition, machine builders have to consider not only technical feasibility, but also factors such as energy efficiency, space requirements and maintenance.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

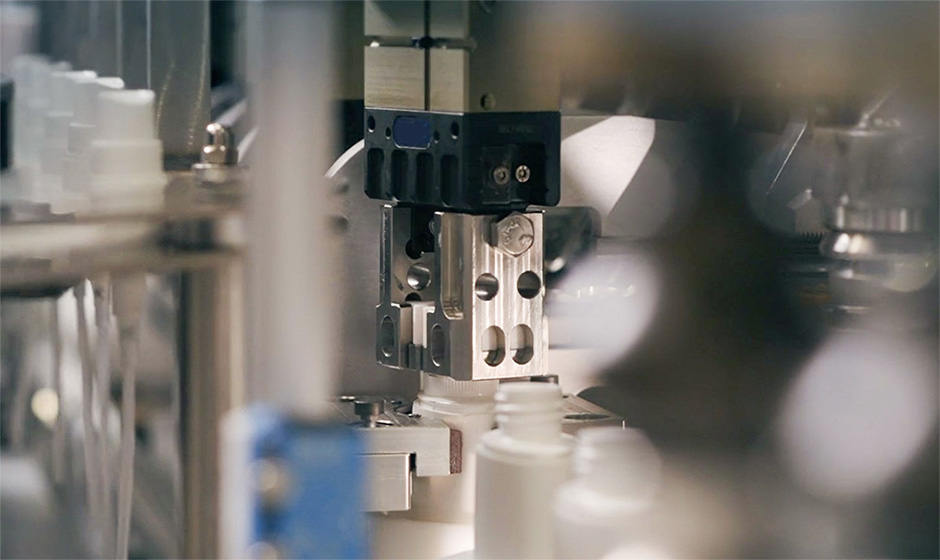

“The Z-axis must also be designed by the machine builder. This is a very complex challenge for the screwing process of our products, as they are offered in a wide variety of formats, all of which have to run on this one machine,” says Mr Vaas, addressing a common problem for many machine builders. For this reason, LinMot offers the PR02 linear rotary motor for linear rotary motion, which, unlike competing products, is an all-in-one solution that meets the various engineering requirements. PR02 motors are also installed in APA-Tech’s ’99’ filling line to perform all motion sequences of the capping station: The six linear rotary motors installed alone can be used to grip, move and insert the spray heads, and then tighten them with torque once the threaded neck has been found without difficulty. “Thanks to the PR02, we can perform completely different motion sequences with a single drive – what more could you want?” says the managing director, praising the outstanding versatility of LinMot’s PR02 motors.

«Thanks to the PR02, we can implement motion sequences that are 100% different from each other – what more could you want?»

Integrable options such as hollow shaft for air feed-through, magnetic spring for passive load compensation, pusher, force and torque sensor – all in a single housing in the PR02.

The hollow shaft of the linear motor allows air to pass through the entire module for the operation of pneumatic grippers. There is no need for additional hoses.

«APA-Tec has extreme speed requirements», explains Managing Director Vaas, when asked why LinMot was also chosen for pick-and-place applications. Thanks to the small moving masses, LinMot drives can operate reliably at high cycle rates without sacrificing precision. This efficiency not only reduces production costs, but also energy consumption compared to conventional drive solutions.

The broad product portfolio and modular system also allow flexible adaptation to a wide range of automation requirements. From complex motion sequences to simple pick-and-place applications, LinMot drives can be individually configured and seamlessly combined into a wide variety of multi-axis and handling systems. This versatility and adaptability makes LinMot products the ideal solution for modern pick-and-place processes where speed and precision are crucial competitive factors.

«LinMot components speak all the major languages of the control world, allowing smooth and efficient integration into control architectures.»

LinMot actuators provide high repeatability, ensuring that each part is placed in exactly the right place, which is essential when placing the caps. LinMot linear modules and grippers can be combined into a wide variety of pick-and-place systems.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information