Design flexible and dynamic filling and closing processes. With linear motors, filling, closing, and packaging processes designs can be much more dynamic, precise, and especially flexible than with pneumatic cylinders. Ever since Chocolat Frey AG recently expanded their production of the highly popular Napolitains, this large Swiss chocolate maker has benefited from the advantages of advanced technology, producing a wide assortment of very small chocolate wafers with even greater quality, process reliability, and productivity.

When Manfred Leuenberger from Chocolat Frey AG extends the invitation to visit his company›s most recent expansion, visitors are caressed by the aroma of fresh chocolate the moment they enter the production hall of the traditional Swiss company, which opens into a glass-enclosed hallway. No wonder, as the passage leads through the area where the raw chocolate mixture for the chocolatier›s 2,500 or so products are freshly prepared and stored in tanks, as the technical manager of the confectionary division explains. But before the visitor can get a look at the latest machine acquisition — a highly modern system for producing small chocolate wafers known as Napoiltains— a stop in the changing room is needed to put on hygienic clothing. Then it›s just a few steps downstairs and the visitor stands before the new machine, which is nearly as tempting to the visitor as the products that are made on it.

Manfred Leuenberger, technical manager in the confectionary at Chocolat Frey AG always has an eye on technology. The potential for improving production and making it more flexible with linear motor solutions from LinMot is inspiring to the trained industrial mechanic. (Photo: Rossmann)

Production capacity for Napolitains increased fivefold

The starting signal for this new system was given back in 2013, when the little chocolate wafers began to show great success. Two older lines, built in 1988 and 1990 and used through the present day, were already running at full capacity. Due to the growth in demand, a central requirement in the specification for the molding line was substantially higher output compared with the previous systems. While the latter can produce a maximum of 400 kg of filled or unfilled Napolitains per hour, the new system needed to handle up to 2 tonnes, or around 6,000 wafers, in the same time period. The machine builder that had been responsible for the older lines met these requirements by applying the latest technology. A linear motor from LinMot plays a central role, fulfilling the task of lifting up the plastic molds, about 850 x 380 in size with cavities for 225 wafers (25×9), from the transport belt to the stationary dispensing nozzles.

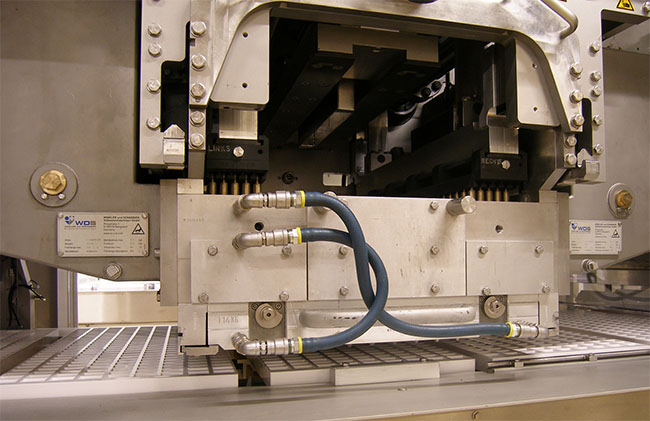

The molds are raised slightly toward the stationary dispensing nozzles in order to prevent undesired spatter and air bubbles. (Photo: Rossmann)

Molding with no bubbles or spatter

«When the molding system pours the liquid chocolate into the mold, the latter is raised to keep the distance between the filling level and the dispensing nozzle to a minimum,» explains Leuenberger. «This is how we prevent air bubbles and spatter.» On the older lines, a pneumatic cylinder raises the molds. A first glance at this process, however, reveals the weakness of the cylinders powered by compressed air. The motion is jerky and the mold drops rather roughly back onto the conveyor rails. With a linear motor, in contrast, the entire motion sequence is more gentle, despite the increased dynamic requirements, which protects the mechanism and the product. Less obvious, though no less significant, is another advantage of the electrical direct drive technology for the end user. «With its integrated measurement system, the linear motor allows significantly greater accuracy in positioning the mold, so that we know precisely where the mold is located at every moment,» explains Manfred Leuenberger. This has made it possible to exactly maintain the optimal distance between the fill level and the mold at all times, with a precision in the range of tenths of millimeters.

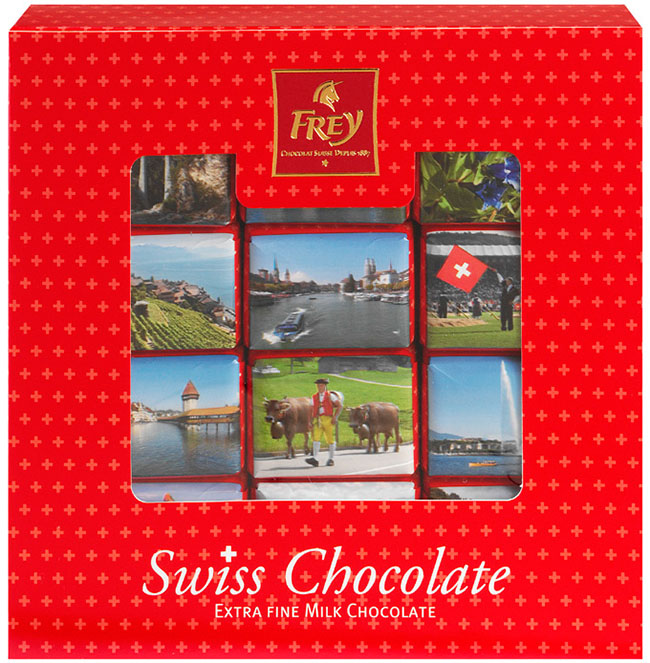

Increasingly popular with consumers: small chocolate wafers with coffee or as an occasional snack. (Photo: Chocolat Frey, Website)

Customized motion profiles protect product and mechanism

Different motion profiles can also be implemented without a problem, matched precisely to the individual requirements of the product and the filling process. «This is not possible with pneumatics, but it is a real advantage, especially for filled products, as it allows us to distribute the chocolate mixture optimally in the mold. This improves the reliability of the process and gives us greater freedom in designing the production process,» adds the Chocolat Frey AG technical specialist. The ability to individually adapt the motion profile can also be used to minimize the loads on the product and the mechanism during the production process. Since the direct electric drives have been in use, it has also been possible to switch between different profiles at the push of a button. This means that product changes take less time.

A controller from Bosch Rexroth (Indra-Control L65) handles the coordination of the numerous axes on the new molding machine, as well as calculating the motion profiles of the LinMot linear motors. This allows Chocolat Frey to react rapidly and flexibly to new product requirements. (Photo Chocolat Frey)

Powerful linear motors from LinMot

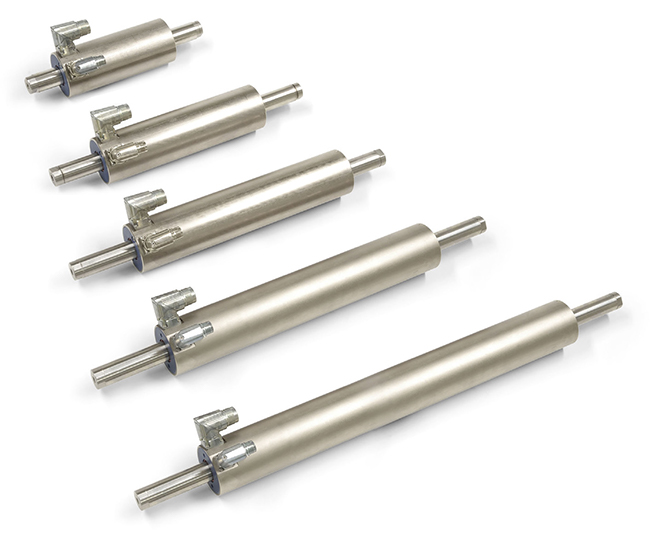

The designers of the molding machine decided to use a tubular linear motor from the LinMot P10-70 series, with a stroke of 90 mm. The PS10-70x160UBL-QJ stator with encoder and the PL10-28×390/340 slider are combined with a matching mounting flange that also serves as a heat sink. Because the motor is mounted outside of the hygienic area, it does not have a higher protection class. For more challenging applications, however, LinMot also has INOX and ATEX versions available. The machine builder chose the P10-70 series for a good reason. The motors in this series have a three-phase winding and are the most powerful motors in the LinMot catalog. They can produce a peak force of up to 2,500 N. Thanks to their modular design, their strokes can range between 10 and 1,770 mm. Speeds of over 5 m/s and accelerations of over 100 g guarantee very short positioning times and high cycle counts. By eliminating the play from mechanical components such as gearboxes or gear racks, linear motors with measurement systems of appropriate resolution can not only be positioned precisely but also require substantially less maintenance than pneumatic cylinders or brushed motors. Unlike pneumatic solutions, the force of the linear motor does not drop off over time, so that maintenance work is needed only at longer intervals.

The linear motors in the P10-70 series are the most powerful motors in the LinMot catalog, with peak forces of up to 2,500 N. Thanks to their modular design, their strokes can range between 10 and 1,770 mm. (Photo: LinMot, Catalog page 442)

Optimally tuned combination of controller and motor

Power is supplied to the linear motor on the Swiss chocolatier›s molding machine by a LinMot E1400 servo controller with a direct 400 V feed. LinMot has made sure, however, that the motors also work just as well in combination with various high-performance drives from other manufacturers. The builder of the molding machine, however, used a customized E1400 with an integrated Sercos III interface to connect to a Bosch Rexroth IndraControl L65 motion controller with a configurable Sercos III interface. The machine controller in this configuration calculates tailored motion profiles for the individual products and molding processes, so that the requirements of all the various products can be met with the greatest flexibility at the press of a button. This guarantees gentle handling of the delicate products with problem-free, gentle motion sequences.

The LinMot controller gives the machine builder great freedom in selecting the control system manufacturer, as variants of the E1400 are available for other common industrial bus systems such as EtherCAT, POWERLINK, ProfiNET, Profibus, or Ethernet/IP.

Chocolat Frey AG responded to the rising demand back in 2014 by commissioning a new production line and increasing production capacity fivefold. (Photo: Rossmann)

Reliable and efficient in action

«After over a year in action, I can say that the linear motor solutions from LinMot has proven it›s worth,» says Leuenberger in conclusion. Visibly impressed by the potential of the direct drive technology, the technical manager of the confectionary at Chocolat Frey sees a positive future for LinMot linear motors in his plant. «There are still a few applications, for example in the filling area for packaged finished products, where it makes sense to replace the usual pneumatic cylinders with linear motors.»

Read more about the linear motors

The traditional company Chocolat Frey AG produces almost 2,500 different chocolate products in Switzerland (Photo: Chocolat Frey)

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information