New linear rotary motors for precise screwdriving and closure applications. Closure processes can be made much more flexible and efficient with direct-drive linear rotary motors than with systems that rely on lift cams, pneumatic cylinders, or ballscrew drives to produce the linear motion. For filling and packaging applications, where great precision and process reliability are needed, LinMot has now brought to market linear rotary motors with integrated sensors. They are not only extremely reliable and precise, but also collect process data for every closure operation.

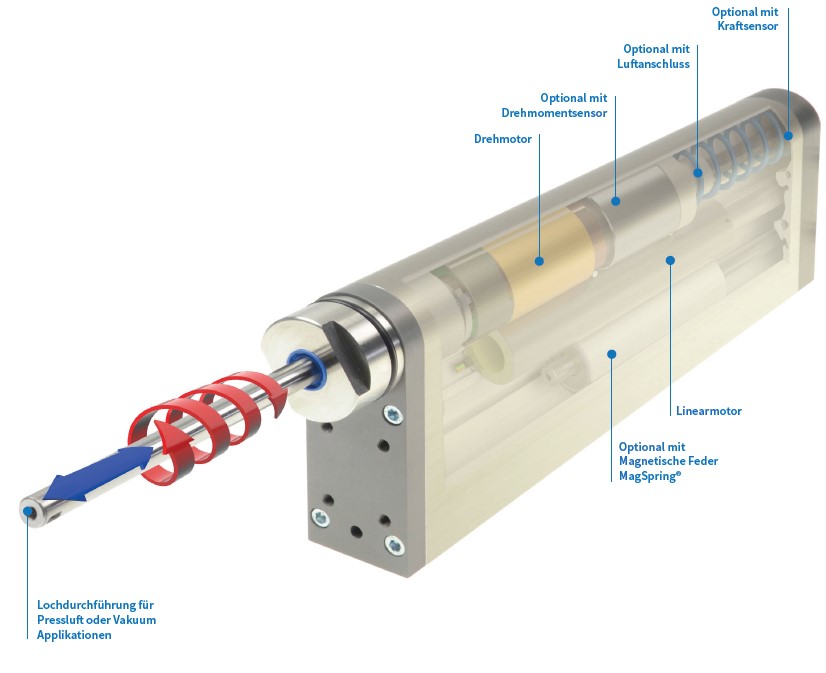

Construction PR02 linear rotary motor (Photo: LinMot)

Excessive variation in closure force, torque, or press force means that the entire package unit needs to be scrapped. A deviation of just a few millinewton-meters from the specified torque is often enough to trigger this scenario. Such tough requirements are placed on the closure process by a rising number of applications in the food and beverage industry. The demand for exceptionally delicate solutions is growing accordingly. Variant production, zero-defect processes, and modern, data-hungry industry 4.0 concepts also see to it that screwdriving and assembly processes need to be more flexible and better controlled than ever before. This means that the torque and angle of rotation of the rotary drive, and the feeding force and position of the linear drive, are always known at any time during the combined linear rotary motion, so they can be precisely controlled. LinMot has now presented a completely new series concept or linear rotary motors, with unprecedented monitoring and precision execution of linear rotary operations.

Greater precision with integrated measurement

The new PR02 series of motors not only combines a linear motor and a servomotor in a common housing, it also provides more space for additional optional features. Users can order the rotary motor with an integrated torque sensor and a force sensor. This means that the actual values achieved for the process parameters of torque, angle of rotation, stroke position, and feed force can be captured and verified continuously with high resolution, reproducibility, and precision. The precision of the force and torque sensors on the PR02-52 model motor, now available in series (100 mm max. stroke, 255 N max. feed force, 2.2 Nm max torque) meets or exceeds 1% of the nominal value. With the optional torque measurement shaft, with a measurement range of 2.5 Nm, the accuracy of the measurement results is (+/-) 0,025 Nm. Values collected in this way can be used to document every closure operation in detail, or for additional process analysis, And can be transmitted directly from the motor to the PLC via an analog signal interface, or by the servocontroller via fieldbus. They are available there to set up closed-loop control circuits or for additional analysis.

Online diagnostics and troubleshooting

The values can be evaluated online or offline to gain insight into the closure process. It is possible to tell for every application not only whether a screw is too tight or too loose, but also whether it is the wrong size, bent, cross-threaded, or stripped. Missing washers can be detected, as can broken workpieces and tools. Values that change slowly indicate that maintenance of the mechanical components is imminently necessary, or that the tool is worn. Because motion profiles direct drives can be freely programmed, and the sensor data is available in real time, any faults that occur can be corrected immediately as needed, or the packaging unit can be rejected automatically or prepped for rework. An improperly installed closure can be unscrewed again immediately to shorten rework time or make disposal easier. By eliminating external sensors, and their associated wiring and moving parts (such as cable trays), they simplify the design and maintenance of the closure system. When the linear rotary motor is installed vertically, the machine designer can also install compensation for the moving load without additional external components. This prevents the axis from dropping when the power is off, as the motor housing also has space for a MagSpring magnetic spring. The LinMot designers have even incorporated a vacuum/compressed air pass-through in the book-shaped, hard-anodized housing of the PR02-52, just 399x135x50 mm in size. Despite its concentrated power, it has no cooling fins, angles, or cavities that are hard to clean, which means this motor is perfect for use in a clean-room environment.

A member of the PR02-38 family (Photo: LinMot)

Reliable data due to redundancy

The end user also benefits from the high level of integration of the LinMot solution. The screwdriving system is significantly less complex, requires less space, and can be replaced more simply and quickly in case of a failure. The reduced number of parts also means failures are less likely and logistics are simpler. But even more important for safety-related applications is that the data from the integrated sensors can be verified using redundant information from the servocontroller current data. For example, if a torque sensor provides a value for the torque that does not match the specified value used to actuate the rotary motor, then there may be a defect in the torque measurement shaft that might have remained undetected without the redundancy.

A product family with a future

If you don›t need such delicate closure motions or reliable sensor data for your application, you can leave the optional sensors off of the PR02 motor, or use the PR01 series of linear rotary motor. In both cases, the specified values for the motion components are available from the servocontroller. The two series of motors do not have overlapping applications, due to their different form factors (PR02: linear and rotary motors in parallel; small, thick book format; PR01: linear and rotary motors in line; slim, cylindrical form factor), so LinMot is continuing to expand both series. The company has announced the PR02-88 for the fall of 2018. This linear rotary motor has a maximum stroke of 300 mm, nominal force of 145 N, and torque of up to 8.9 Nm. This makes it perfect for applications such as trigger and pump-spray closures. Also planned for the fall is the launch of the LinMot PR02-38 as a smaller version of the PR02-52. It is perfectly suited for lighter pick & place, bending, and press-on operations. In parallel with this, the PR01 family is being expanded with the PR01-70 linear rotary motor. This model is somewhat more compact but has nearly identical force parameters as the PR01-84, which has been available for a while.

Advantages of direct drive technology

The direct drive technology used with all of these linear rotary motors is also responsible for other characteristic product features. For example, it makes it possible to generate linear and rotary motions without belts, gearboxes, screw drives, or pneumatic cylinders, and to produce stroke curves without contact. The motions can be controlled independently of each other with programmable profiles. Linear rotary motors combine maximum flexibility with outstanding dynamics and speed, along with exceptional availability and nearly zero maintenance. Compared with pneumatic solutions, they are also cleaner, quieter, more compact, and more energy-efficient. The diverse advantages of these new, highly integrated linear rotary solutions have convinced many advanced machine builders, who have had great success in their initial applications with end customers. This high level of interest means that many more machine builders will get on board and use this new technology.

You are currently viewing a placeholder content from Yumpu. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information