Guaranteeing optimal packaging results every time, even when product characteristics vary and product types change frequently, is one of the greatest challenges facing a machine builder. Alpenland Maschinenbau GmbH, or ALPMA for short, has taken on and successfully overcome this challenge. Its new MultiSAN film wrapping machine packages round and rectangular soft cheeses with no compromises, as well as cheeses in karospar, cylindrical, and half-moon formats. Difficult reconfigurations and long setup times are no longer needed.

«There are cheese makers today that make only a few types of cheese, but nevertheless change over their production every two or three hours because they produce every order by the truckload, » reports Helmut Eitermoser, the designer of the MultiSAN. This is a special case of frequent product changes, which other ALPMA customers are also face with for various reasons. The reasons for smaller and smaller batches are typically the same as in other industries: customer-specific product requirements, shorter product life cycles, and increasing product variety.

No more compromises

Until now, cheese makers used packaging systems in which a mechanical master shaft with cam drives mounted on it drove the synchronous motion of the individual mechanisms. «These cam machines were and are the right solution for packaging just one type of product. They are very precise, cost-effective, and durable,» says Helmut Eitermoser. «Two similar format shapes—such as round and halfmoon— and different sizes with the same shape can also be processed on these machines with a reasonable effort. This does, however, always require a compromise, which means simply that the packages for each product version are less than optimal.»When several different products are to be packed in a folded or wrapped package on the same machine with rapid changeovers, the cam machine reaches its limits. Extensive reconfiguration or even machine replacement is required before a product changeover. In France, the homeland of soft cheeses and wrapped packaging, the call for a flexible solution has recently become louder and louder. As the world›s leading provider of process equipment, systems, and cutting and packaging solutions for cheese makers, ALPMA has met this demand by developing the MultiSAN.

The new film wrapping machine from ALPMA can process a substantially wider range of products with no changeover, thanks to the use of LinMot linear motors. (Source: ALMPA)

Electronic master shaft and cams

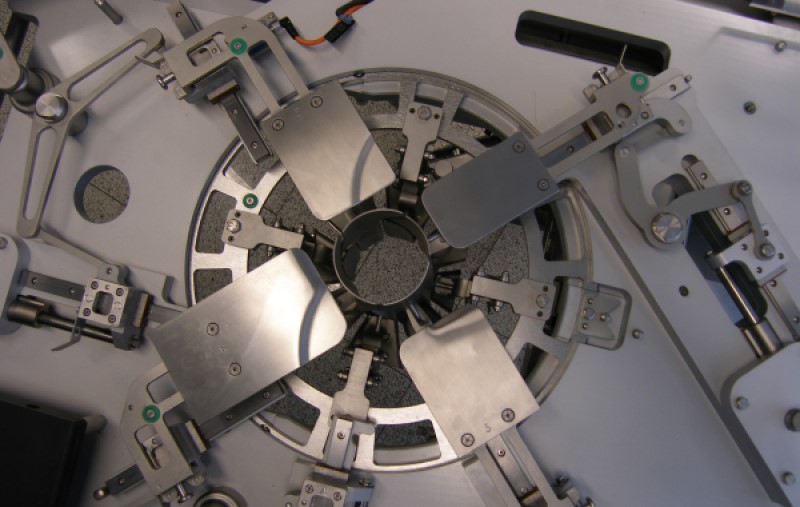

The high flexibility that the new film wrapping machine provides is not a matter of chance. The necessary basis that ALPMA came up with required the use of cutting-edge direct drive technology in combination with a virtual master shaft and electronic cams, which have completely replaced their mechanical counterparts. The envelope folds under the cheese, typical for wrapped packaging, are now produced by means of four horizontally mounted LinMot linear motors that each drive one shutter blade via a linkage. Once the cheese has been wrapped in the packing film by the machine, and has been fixed in place on a round plate by a gripper, the shutters press the protruding film together on the bottom of the product in rapid succession, thus producing the desired fold pattern. Another linear motor axis moves the cheese off of the round plate onto a belt that transports the cheese to the next stations.

LinMot linear motors: unrivaled power density

«Demo units have shown that rotary servomotors are not well suited for this task, because they take up too much space,» says Helmut Eitermoser, explaining the basic decision in favor of linear motors. In a subsequent evaluation phase, LinMot was able to win out over several competitors. «Only the LinMot motors had the small dimensions that we wanted and the performance that we needed,» says the designer in a nutshell. «If the other manufacturer›s motors were even able to achieve the same performance at all, they were still twice the size.»The MultiSAN uses model PS01-23x160HHP-R motors that have a diameter of 23 mm (stator)—not including the plug connection on the end—but nevertheless are able to produce a peak force of 130 N when coupled with the LinMot E1130-DP-HC controller. The matching sliders are available as standard products in many variants, for strokes from 20 to 780 mm. The version selected for the MultiSAN has a stroke of 120 mm.

LinMot linear motors have a round form factor that produces very high power densities. (Foto: LinMot)

Complete format changeover in a few minutes

This space-saving form factor of the linear motor also decisively contributed to the fact that the machine takes up the same floor space as the comparable version with a mechanical master shaft, the SAN 80 TS. The cycle time also matches: both run at up to 80 cycles. The commonalties end there, however. The MultiSAN is much more modular in construction, due to the use of direct drive technology, and is designed to be used more flexibly. ALPMA combined the mechanical unit with the shutter drives into one module that is used in several places on the machines. It is designed to function as a heat sink for the linear motors as well. Changing formats on the MultiSAN has become conceivably simple due to the consistent modular construction and the use of electric drives instead of a mechanical master shaft. In just a few steps, the closure module can be removed and installed in a different position, without having to disconnect the flexible supply cable for the linear motor. Then the corresponding program just needs to be started from the user-friendly touchscreen controls, and then the same machine that had been processing oval cheeses just a few minutes ago, for example, can now package a cheese in the karospar format. In addition, various configuration sets (format sets) can be used to expand the range of use of the MultiSAN.

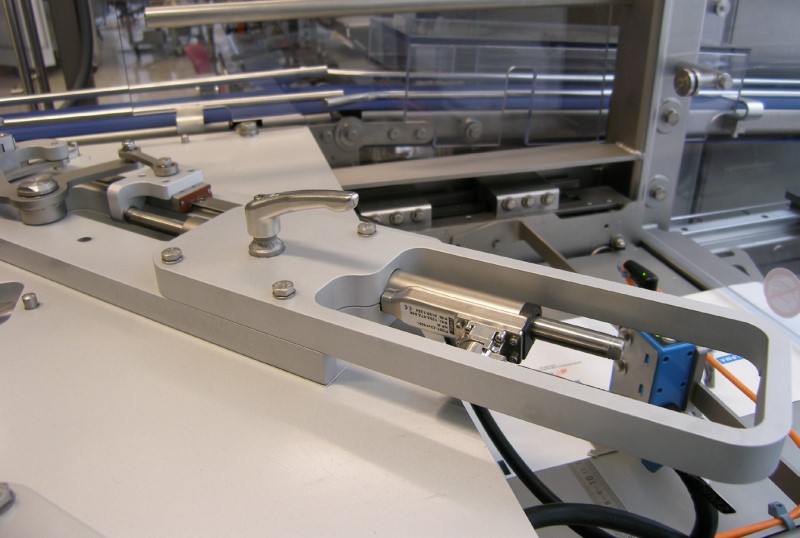

ALPMA built the LinMot motors with the shutter drives into one module that is used in several places on the machines. It is designed to function as a heat sink for the linear motors as well. (Foto: ALPMA)

Optimal packaging results every time

«We have also made use of the very sensitive and direct reaction performance of LinMot linear motors to provide the operator with an instrument for reacting to variations in product consistency,» adds Helmut Eitermoser. «The responsible parties on site can thus set their own parameters for various consistencies, so that the machine operator can adapt the machine settings to changes in product characteristics just by pushing a button while operations are running.»This means that the MultiSAN ensures optimal results every time, not only for different product formats but also for the unavoidable slight variations in the production process.

By using direct drive technology, the MultiSAN has been decoupled mechanically so that sensitive components can be folded back out of the foam cleaning area. At the same time, this cleaning position improves access to the machine for maintenance. (Foto: ALPMA)

Machine sales doubled

With these characteristics, the new packaging machine from ALPMA touched a nerve in the marketplace, as the impressive sales numbers confirm. In just the first few months after the machine was introduced, they were double the number that had been typically sold in the same period of time. ALPMA is not resting on this success and is already working on further developments of the MultiSAN, as the company›s designer divulges. «We have not yet begun to exploit all of the capabilities of LinMot linear motors. We are working on increasing the throughput of the machine to 100 cycles.»But this is still not enough. Until now, the linear motors have been actuated by LinMot controllers that communicate with the machine controller via PROFIBUS. In the next step, a switch to LinMot controllers with the Sercos III interface is planned, which can be directly integrated in the machine controller from Schneider Electric. «We will then have even more precise control and require just one programming environment,» says Helmut Eitermoser, looking expectantly to the future.