Flexible and fast as lightning: Direct electrical drives can be used to build pick&place modules that are highly efficient, precise, and dynamic. They are also more flexible, more compact, and require less effort to install and maintain than their pneumatic or cam-driven counterparts. The Swiss company PARO AG has made access to these benefits particularly easy for themselves and their customers by developing the PARO Blitz. The machine builder uses this pick & place system in assembly lines and specialty machines that are at the top of their league in terms of productivity.

«The typical cycle time for assembly lines has been cut nearly in half within just a few years, and is now approaching one second,» says Gregory Kyd, technical manager at the Swiss company PARO AG. «Pick & place solutions that can meet that speed could still be done with pneumatics or cams. But direct drives are much more efficient, use less space, and are more flexible, as our PARO Blitz demonstrates.» This is a particularly compact pick & place system with one horizontal and one vertical linear motor, moving a maximum load of 5 kg and achieving up to 60 cycles a minute, depending on the stroke and dynamics required. A simple dovetail mounting system ensures fast, precise adaptation for grippers and other handling units. Thanks to the fine adjustment of the mounting system and the precision of the linear drives, movements are repeatable to +/-0.05 mm. Among the substantial advantages over pneumatic pick & place systems is the greater flexibility of the direct-drive technology in the PARO Blitz. Because movements are powered and controlled purely electrically, functions can be provided on the human-machine interface that allow the operator to select and initiate pre-programmed motion sequences at the press of a button. Variant manufacturing can also be implemented just as simply. «Pneumatic cylinders, in contrast, can only do more or less point-to-point movements. Intermediate stops required additional stop bolts, and every change in stroke means repositioning the limit switches,» cautions Gregory Kyd.

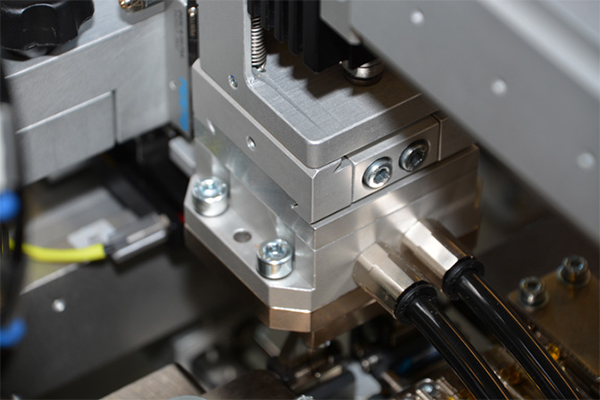

A dovetail mount on the PARO Blitz enables simple adaptation of grippers or other handling units. Thanks to the fine adjustment of the mounting system and the precision of the linear drives, movements are repeatable to +/-0.05 mm. (Photo: Rossmann)

Compact and scalable

The reason that PARO technicians have been able to make the Blitz so compact is largely that the specialty machine builder decided to use LinMot linear motor components, explains the company›s technical manager. «When we checked out the market prior to launching the PARO Blitz in 2014, LinMot quickly landed on the short list due to its space-saving design and the exemplary construction of its solutions.» In the end, LinMot was the final winner in part because of its wide spectrum of products, which includes a number of different sliders and stators, complete linear motors with matching controllers and «magnetic springs» (MagSpring) for weight compensation, and linear-rotary motors. On the basis of this spectrum, PARO has developed several variants of the PARO Blitz for strokes from 50 mm to 190 mm. PARO can therefore frequently use the pick & place module in assembly lines, as Gregory Kyd explains: «As of the end of May 2018, over 200 of the modules are working reliably in over 30 systems.»

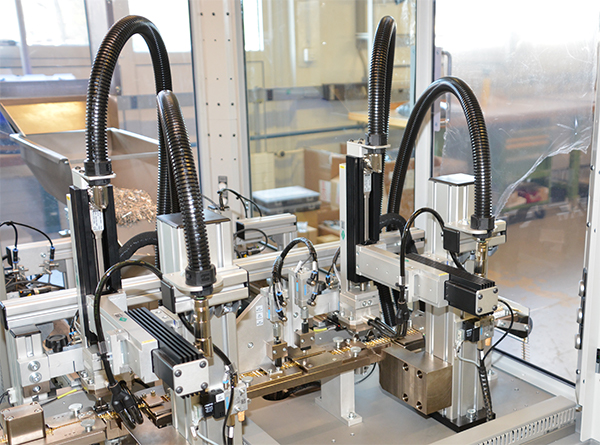

Thanks to linear motor components from LinMot, the PARO Blitz pick & place module developed by PARO AG is not only highly dynamic, but is also particularly compact, so it can be integrated in systems with tight space constraints. (Photo: Rossmann)

Data source for Industry 4.0

To monitor the position or motion of a pneumatic cylinder, or to use them as control parameters, requires separate sensors. With linear motors, however, the measurement system is already integrated. The servocontroller can thus provide data for further processing, such as stroke or force values, on every single pick & place operation. This data can be used, for example, to automatically compensate for temperature-based changes to the mechanical portions of the pick & place system. With pneumatic or cam-driven systems, the operator must make manual interventions and adjustments after the machine has stopped or if the ambient temperature varies greatly. The air supply to pneumatic cylinders must also be checked for leaks, and cam discs for wear, on a regular basis, and end stops and shock absorbers need to be replaced. Because a linear motor operates without contact and is therefore maintenance-free, maintenance work for the PARO Blitz is reduced to a minimum. The integrated guide rails used to support the linear motion do not require any additional lubrication. The reliability of the pick & place module is proven by a demonstrator at PARO AG: a module has been in operation there for 190 million cycles, as of the end of May 2018, without any maintenance or unplanned interruptions. And even if a Blitz needs to be replaced at some point, this goes much faster than for a pneumatic system, with its myriad compressed-air hoses, or a cam-driven system, with its mechanical couplings. The Blitz can also be set up as an electrical module and functionally tested prior to being integrated in the line, so maintenance and repair times are also short. To those responsible for shorter cycle times at PARO, the significantly higher dynamics of the direct-drive technology are almost more important than high availability of the pick & place system. «Under certain conditions, pneumatic cylinders can also hit 60 cycles per minutes, but this takes a lot more effort.» Double-acting pneumatic cylinders require two compressed-air hoses each, and possibly a position sensor, while a direct drive needs just one electrical cable. This has clear benefits during installation and saves space, as Kyd explains: «By eliminating hoses, the PARO Blitz takes up just half the space, and installation takes just one-third the time, in comparison with its pneumatic counterpart.»

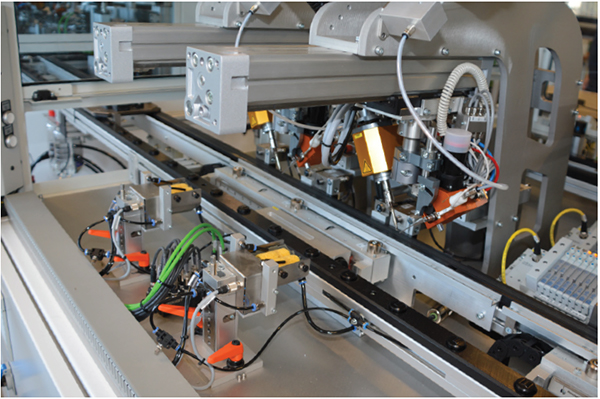

In addition to classic pick & place operations, the PARO Blitz can use the integrated measurement system for the linear motors, and the controlled force that it can apply, for pressing or bending processes. (Photo: Rossmann)

More than a pick & place system

Thanks to the superior features and compact form factor of the direct-drive pick & place system, the potential applications for the PARO Blitz extend well beyond simple pick & place operations. PARO incorporates it in assembly lines for pressing and bending operations, integrates it in area gantries, and uses it for rapid loading functions. In one current system for assembling an electronic component for a building technology application, with 31 assembly, processing, and test stations, the total number of Blitzes installed adds up to 30 units. On top of that are 3 linear motor axes for other positioning tasks. They are controlled by 33 servocontrollers from LinMot with Profinet interfaces. The system consists of a total of three assembly cells, each with a footprint of 2×2 meters, linked by a Paromat double-belt transfer system.

The most challenging task, which is also the core process of the line and is handled by a PARO Blitz in the assembly line, is gripping and positioning the two terminal lugs of a sensor to be mounted on the circuit board for the component. The position of the 0.2 millimeter-thin leads is captured by an image processing system. A three-dimensional motion of the PARO Blitz and the portal on which it is mounted is then individually calculated to capture the leads for each lead and sensor. The lead is captured by a gripper, guided to the circuit board, and soldered there. «This would be simply impossible with pneumatic or cam-based pick & place solutions, because they do not support precise, numerical positioning,» adds Gregory Kyd. «They would also not be able to meet the required cycle time.»

PARO AG also uses the principle of the PARO Blitz to implement rapid loading units. The workpiece carrier is drawn into the soldering station from the double belt conveyor in a fraction of a millisecond, or a station is skipped in order to extend the available processing time or to maintain the required cycle time. (Photo: Rossmann)

Linear motors guarantee short cycle times

Other copies of the pick & place module perform assembly steps, such as placing an LCD display, a rubber contact strip, the circuit board in a lower housing, a battery (different for each variant), a security seal, and positioning the components in test stations spread throughout the system. In addition to these classical pick & place operations, rapid loading units constructed using the PARO Blitz principle take on the task of rapidly changing out workpiece carriers in the line. The workpiece carrier is drawn into the soldering station from the double belt conveyor in a fraction of a millisecond, or a station is skipped in order to extend the available processing time or to maintain the required cycle time. Another linear motor provides the necessary dynamics when stacking and unstacking the finished, assembled components. A MagSpring component compensates for the weight of the vertical axis and guarantees secure positioning in case of a machine stop.

More about the advantages of linear motors over pneumatic drives