As the widespread implementation of sustainability efforts at the business level continues to grow, finding ways to make your production eco-friendlier is more important than ever. However, when it comes to improving the sustainability of your motion applications, navigating your options can be challenging.

Whether you are looking to meet your company’s Environmentally Preferable Purchasing (EPP) Program guidelines, ESG (Environmental, Social and Governance) goals or just getting started on your sustainability journey, there are many options and even more jargon about why to choose them. But it doesn’t have to be difficult to choose the right one.

From providing energy savings to reducing your carbon footprint, read on to learn why LinMot USA’s electric linear motors are the greener way to power your linear motion applications when compared to air.

You are currently viewing a placeholder content from Default. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

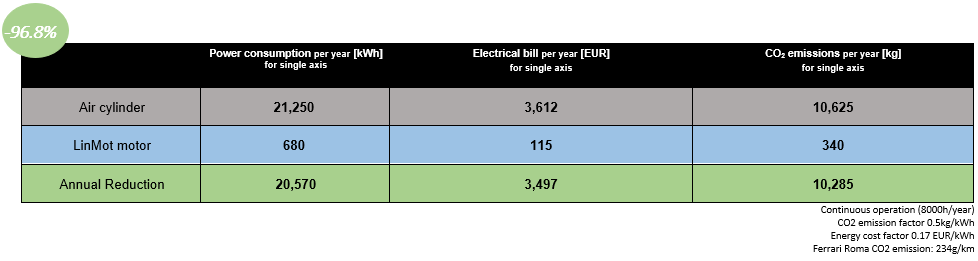

Air compressors require a substantial amount of energy to run. So much so that they are often one of the largest drivers of energy consumption in production facilities. With LinMot linear motors, you can achieve energy savings of over 95% when compared to pneumatic cylinders. In fact, some applications boast energy consumption totaling only 3.2% of what pneumatic cylinders equipped in the same machine would.

Using fossil fuels results in carbon dioxide emissions. And since power plants require fossil fuels, energy usage and the demand for fossil fuels go together. This is why reducing your energy usage is essential to lowering Greenhouse Gas (GHG) emissions.

Since they require so much energy, using air cylinders emits a considerable amount of CO2, making them an unsustainable choice and significantly increasing your GHG emissions. By lowering energy usage, LinMot sustainable direct drives can reduce CO2 emissions by nearly 97%, saving you a significant amount of money and reducing your carbon footprint.

Since they have fewer moving parts compared to air cylinders, electric drive solutions are easier to maintain and less likely to break down. This can lead to lower maintenance and total ownership costs over its lifespan. Additionally, fewer parts mean less material waste, further reducing your overall carbon footprint.

Ready to move forward in your sustainability journey? We’ll be with you each step of the way.